High Velocity Oxyfuel Spraying Producing Tungsten Carbide Based Coating Analysis

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 January 2016 14:28

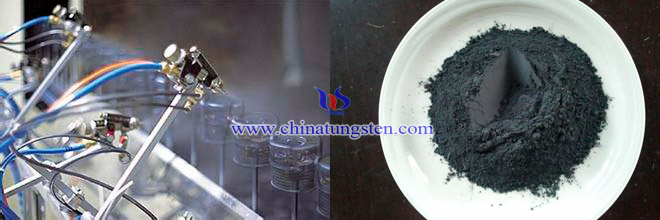

HVOF (high velocity oxyfuel spraying, HVOF) method is the use of hydrogen, acetylene, propylene, kerosene and other fuel, oxygen for combustion, combustion in the combustion chamber or a special nozzle to produce 2100m / s or more over the speed supersonic burning flame. The powder was sent to a supersonic combustion flame to produce molten or semi-molten particles, high-speed impact deposition surface of the substrate to form a coating. Because tungsten carbide has good abrasion resistance, so the tungsten carbide based coatings prepared by HVOF method with good anti-wear, anti-corrosion properties.

Tungsten carbide coating on the resulting analysis found that the coating thickness of 300 microns, deposition efficiency of 55.15% and a porosity of 0.32%. Coating phase mainly composed of WC phase and also contains small amounts of W2C phase and amorphous phase or nanocrystalline phase, but W phase or η (Co6W6C, Co3W3C) does not appear, shows that very short residence time of the particles in the flame stream and the powder decarbonization to a small extent. The main reasons of small decarbonization degree of coating are as follw: (1) no η phase powder; (2) the experimental oxygen flow and kerosene flow design helps to get a relatively low flame temperature; (3) moving faster of spray gun and compressed air cooling during spraying, so that the coating heated degree is low. In addition, the coating powder stored in the WC hard phase, will help improve the wear resistance of the coating.

Testing tungsten carbide coating’s hardness, abrasion and corrosion resistance to salt spray found that the hardness of the coating nearly 1300HV, wear volume is quite small. Coating in neutral salt spray environment 360 hours and still maintain a smooth surface and has a metallic luster, corrosion does not occur, indicating strong corrosion resistance coating. After adding Cr easy since Cr2O3 ceramic layer formed on the surface of a thin coating, thereby improving the corrosion resistance of the coating.

| Tungsten Supplier: Chinatungsten Online www.chinatungsten.com | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com