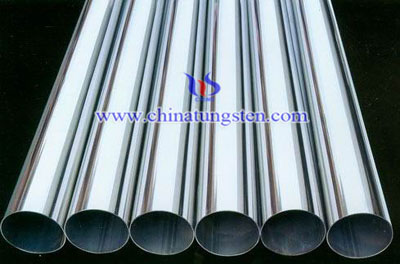

Preparation of Tungsten Tube by Chemical Vapor Deposition

- Details

- Category: Tungsten Information

- Published on Friday, 12 June 2015 18:47

Using WF6(high purity) and H2(high purity) as raw materials, by CVD (chemical vapor deposition) for tungsten tube preparation, its deposition temperature is controlled at 500-700 ℃.

Tungsten tube manufacturing process is as follows:

WF6 and H2 have a chemical reaction, and WF6 reduce to tungsten atoms, then a deposited tungsten layer is obtained on the deposition substrate profile.

After the end of aforementioned process, by melting the matrix in vacuum furnace or chemical etching to get deposited tungsten tube, its shape depends on the shape of deposited matrix, furthermore its size and precision is controllable.

Then, using a density meter to measure the density of the product;

Measuring micro-hardness by micro-hardness tester;

Measuring the tensile strength of the product with universal testing machine;

Observating the metallographic phase with a metalloscope and collecting metallographic phase picture with a digital camera;

Analyzing the deposition content and fluoride residue by using X-ray fluorescence spectroscopy and EDS (Energy Dispersive Spectroscopy);

Residual stress is measured with a diffractometer on tangential and axial product surface.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com