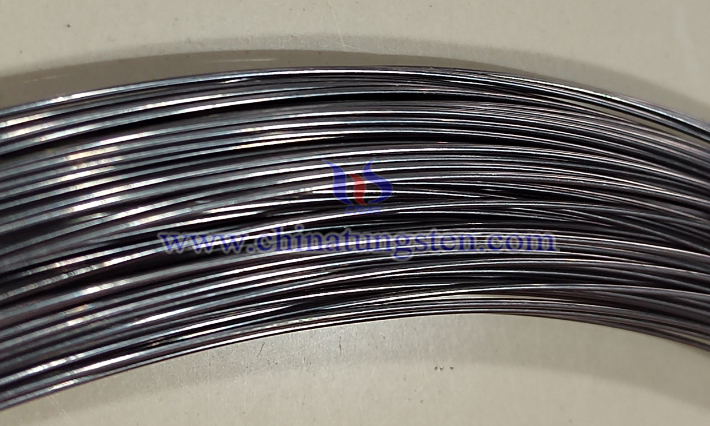

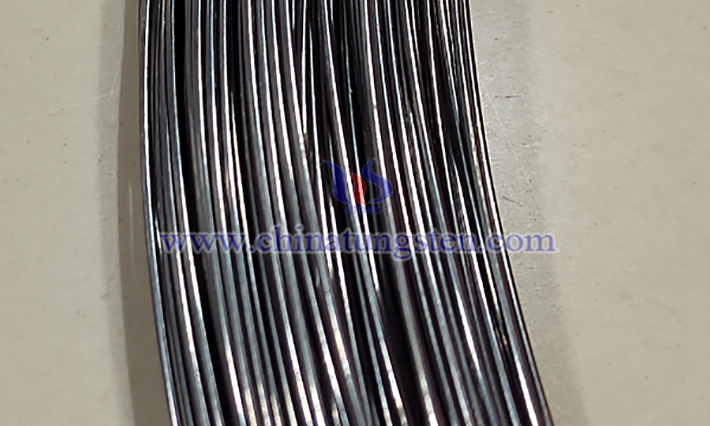

Durability of Tungsten Wire in High-Temperature Furnaces

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:07

The durability of tungsten wire in high-temperature furnaces depends primarily on its material properties, environmental conditions, and usage.

1. Material Properties of Tungsten Wire

High Melting Point: Tungsten has the highest melting point of all metals, approximately 3422°C. Therefore, tungsten wire exhibits excellent heat resistance in high-temperature furnaces (typically 2000-3000°C).

Poor Oxidation Resistance: Tungsten readily reacts with oxygen at high temperatures to form volatile oxides, causing rapid corrosion. Therefore, vacuum or inert gas protection (such as argon or nitrogen) is typically required in high-temperature furnaces to extend the life of the tungsten wire.

Mechanical Strength: Tungsten wire maintains high strength even at high temperatures, but prolonged high-temperature exposure may cause grain growth or recrystallization, making it brittle and affecting its durability.

2. Factors affecting durability

Temperature: The higher the temperature, the faster the evaporation rate of the tungsten wire and the shorter its life. For example, above 3000°C, the volatilization loss of the tungsten wire increases significantly.

Atmosphere: (1) Vacuum environment: Reduce oxidation and extend life, but still need to pay attention to tungsten evaporation. (2) Inert gas: Such as argon can effectively prevent oxidation, but the gas purity must be high. Trace oxygen or water vapor may still cause corrosion. (3) Oxidizing atmosphere: Completely unsuitable, the tungsten wire will fail quickly.

Current and power: Tungsten wire is often used for resistance heating. Excessive current density may cause local overheating and accelerate material degradation.

Number of cycles: Frequent thermal cycles (opening and closing the furnace) will cause thermal stress, causing the tungsten wire to crack or break.

Impurities: Trace impurities (such as carbon and oxygen) in the manufacture of tungsten wire may trigger chemical reactions at high temperatures, reducing durability.

3. Durability optimization measures

Protective atmosphere: Use high-purity inert gas or high vacuum environment to reduce oxidation and evaporation. Doped Tungsten Wire: Tungsten wire doped with potassium, silicon, aluminum, or other materials (such as W-Re or doped tungsten wire) can improve recrystallization resistance and high-temperature strength, extending its life.

Temperature Control: Avoid prolonged operation at temperatures near the melting point. Operating temperatures below 2800°C are recommended to reduce evaporation.

Surface Coating: Applying an anti-oxidation coating (such as a ceramic coating) to the tungsten wire surface can improve durability, but ensure that the coating matches the thermal expansion of the tungsten.

Design Optimization: Optimize the diameter and length of the tungsten wire to reduce current density and minimize localized overheating.

4. Actual Lifespan

The lifespan of tungsten wire varies depending on the application. In industrial high-temperature furnaces under vacuum or inert gas protection (such as vacuum furnaces and graphitization furnaces), tungsten wire can operate continuously for hundreds to thousands of hours, depending on the temperature and environment.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com