Tungsten Wire for Ceramic Sintering Heating

- Details

- Category: Tungsten Information

- Published on Monday, 11 August 2025 19:05

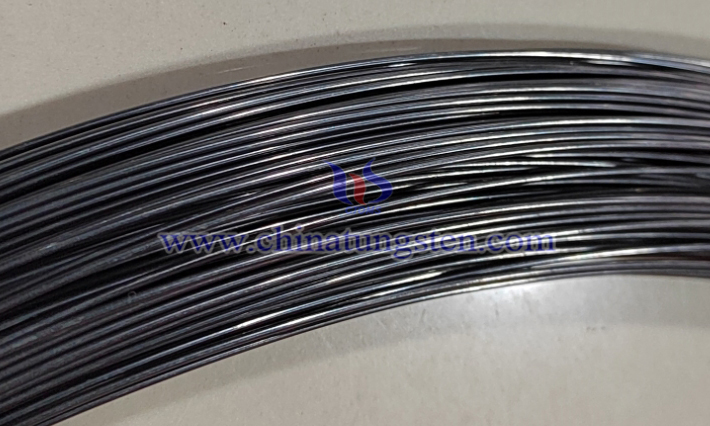

Tungsten wire, as a high-temperature heating material, is often used as a heating element in ceramic sintering due to its high melting point, excellent electrical conductivity, and high-temperature resistance.

Tungsten wire's key characteristics are its high melting point (approximately 3422°C) and excellent high-temperature resistance, enabling it to operate stably in the high-temperature environments required for ceramic sintering (typically above 1000°C to 2000°C). Tungsten has a low vapor pressure and is nonvolatile at high temperatures, ensuring long-term stability. Furthermore, its moderate resistivity and high electrical-to-heat conversion efficiency make it suitable for use as a resistive heating element. Its excellent mechanical strength and oxidation resistance (in inert or vacuum environments) further extend its service life.

In ceramic sintering, tungsten wire is primarily used in the heating systems of high-temperature furnaces. Ceramic materials (such as alumina, zirconia, or silicon nitride) require high temperatures during sintering to achieve densification. Tungsten wires generate high temperatures through electrical current, providing a uniform and controllable heat field. Tungsten wire heating elements are typically arranged in a spiral or mesh pattern to ensure uniform temperature distribution within the furnace, preventing cracking or uneven performance of ceramic components due to temperature differences. Furthermore, tungsten wires allow for precise control of heating rates and temperatures, meeting the stringent sintering requirements of various ceramic materials.

Tungsten wires offer advantages in durability and efficiency. Under vacuum or inert gas (such as argon), tungsten wires effectively resist oxidation, extending their service life. Compared to other heating materials (such as silicon carbide or molybdenum wire), tungsten wires are more stable at extremely high temperatures, making them suitable for sintering high-performance ceramics, such as ceramic-matrix composites used in aerospace applications. However, tungsten wires are susceptible to oxidation in oxygen-containing environments, requiring their use in a vacuum or protective atmosphere, which increases equipment complexity.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com