Quality Control of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 19:03

The quality control of tungsten wire for glass heating involves multiple key links such as raw materials, production, and testing to ensure its stable performance, high temperature resistance and long service life.

1. Raw Material Purity Control:

Tungsten wire needs to use high-purity tungsten powder (purity is usually ≥99.95%) to reduce the impact of impurities on high temperature performance.

The impurity content (such as iron, nickel, silicon, etc.) in the raw materials is detected by chemical analysis (such as ICP-MS).

2. Production Process Control:

Powder metallurgy: strictly control the particle size distribution and compaction density of tungsten powder to ensure the uniformity of the billet.

Sintering: high-temperature sintering (about 3000°C) under hydrogen protective atmosphere, control sintering time and temperature to prevent excessive grain size or pore defects.

Wire drawing: Use a multi-pass wire drawing process to control the drawing rate and mold accuracy to ensure the consistency of tungsten wire diameter (tolerance is usually ±0.01mm).

Annealing: Intermediate annealing eliminates processing stress, optimizes the crystal structure, and prevents tungsten wire embrittlement.

3. Size and Surface Quality:

Use a laser diameter gauge to monitor the tungsten wire diameter in real time to ensure uniformity.

Check whether there are cracks, oxidation or scratches on the surface, which can be detected by a microscope or surface roughness meter.

Surface cleanliness control to avoid oil or oxide affecting heating performance.

4. Mechanical and Electrical Performance Testing:

Tensile strength: Test the tensile strength of tungsten wire at room temperature and high temperature (usually ≥2500 MPa) to ensure its mechanical stability.

Resistivity: Measure the resistivity of tungsten wire (about 5.5 μΩ·cm at 20°C) to ensure the efficiency of electrothermal conversion.

High temperature performance: Test the oxidation resistance and high temperature creep resistance of tungsten wire in a simulated glass heating environment (about 2000-2500°C).

5. Quality Inspection and Traceability:

Each batch of tungsten wire is sampled and tested, and production parameters (such as batch number and process conditions) are recorded for traceability.

Internal defects (such as pores or inclusions) are detected using X-rays or ultrasound.

The finished product needs to pass high-temperature power-on test to simulate the actual use environment and verify stability.

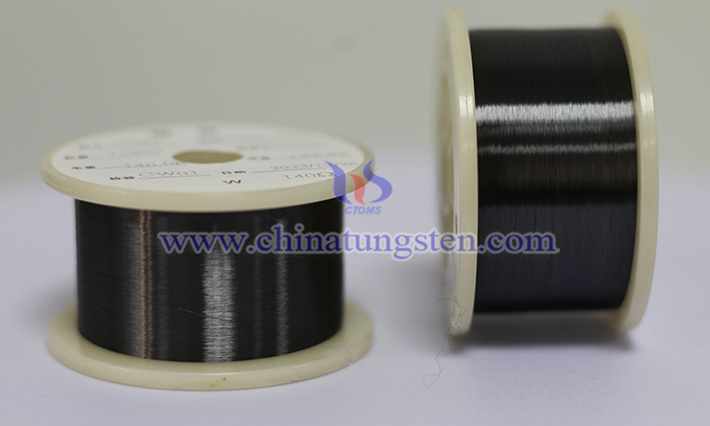

6. Packaging and Storage:

Tungsten wire is easy to oxidize and needs to be packaged in a vacuum or inert gas (such as argon) environment.

The storage environment needs to be dry and low temperature to avoid surface oxidation caused by humidity or high temperature.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com