The Use Environment of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:58

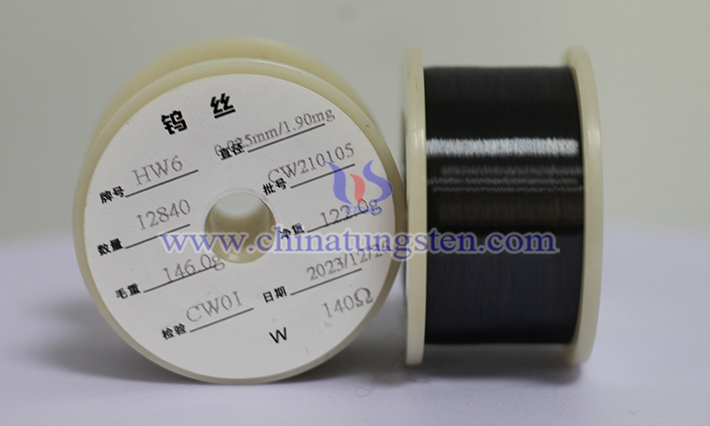

Tungsten wire is often used in glass heating environments due to its high melting point (about 3422℃), high strength and good conductivity, especially in high temperature processes such as glass melting, molding or annealing. The following are the key characteristics and requirements of tungsten wire in the use environment of glass heating:

1. Use Environment Characteristics

High temperature environment: Glass processing usually requires temperatures above 1000℃ to 2000℃, and tungsten wire can withstand such extreme high temperatures without melting or significant deformation.

Inert or vacuum environment: Tungsten wire easily reacts with oxygen at high temperature to form tungsten oxide (WO₃), so it is often used in a vacuum or inert gas (such as argon, nitrogen) environment to prevent oxidation.

High power density: Glass heating requires rapid temperature rise and uniform heat distribution. Tungsten wire, as a resistance heating element, can provide high power density and is suitable for rapid heating needs.

Chemical stability: Tungsten wire is chemically inert to the glass material itself and will not react significantly with molten glass, making it suitable for direct or indirect heating.

2. Specific Application Scenarios

Glass melting furnace: Tungsten wire can be used as an electric heating element to provide the high temperature required for melting glass raw materials.

Glass forming equipment: During drawing, blowing or pressing, tungsten wire is used for local heating to keep the glass in a plastic state.

Annealing furnace: During the glass annealing process, tungsten wire provides uniform low-temperature (relative to melting temperature) heating to eliminate internal stress.

Vacuum or protective atmosphere equipment: For example, in the manufacture of optical glass or special glass, tungsten wire is often placed in a vacuum furnace or an environment filled with inert gas.

3. Environmental Requirements for Use

Prevent oxidation: The oxygen content must be strictly controlled, and high-purity inert gas or high vacuum environment (usually less than 10⁻³ Pa) must be used.

Temperature control: The heating power needs to be precisely controlled to avoid overheating of the tungsten wire, which may shorten its life or break it.

Mechanical stability: Tungsten wire may creep or become brittle at high temperatures, and a suitable support structure needs to be designed to reduce mechanical stress.

Current stability: The resistance of tungsten wire changes greatly with temperature, so a stable power supply and control system must be used to prevent current shock.

Clean environment: The glass heating environment must avoid impurities and the surface of the tungsten wire must be kept clean to prevent volatile substances from contaminating the glass.

4. Precautions

Life management: Tungsten wire will gradually evaporate and become brittle at high temperatures, and must be checked and replaced regularly.

Safety: High temperature and high voltage electrical environments must strictly comply with safety regulations to prevent electric shock or fire.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com