Detection of Tungsten Wire for Glass Heating

- Details

- Category: Tungsten Information

- Published on Wednesday, 25 June 2025 18:53

The detection of tungsten wire for glass heating mainly involves its physical properties, chemical stability and electrical characteristics to ensure its safety and reliability during high-temperature heating. The following are the key points and methods of detection:

1. Physical Property Detection

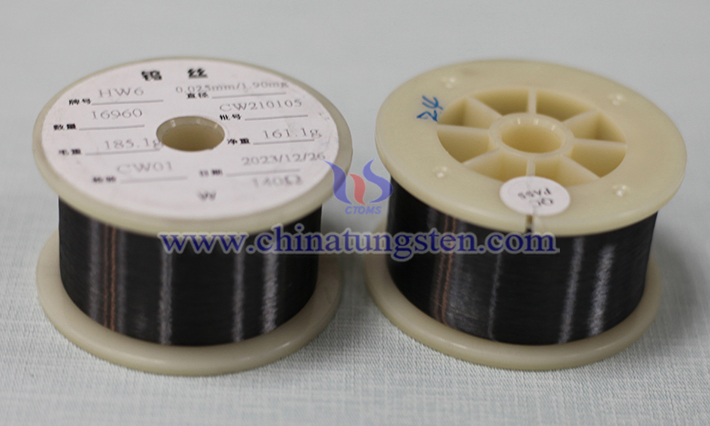

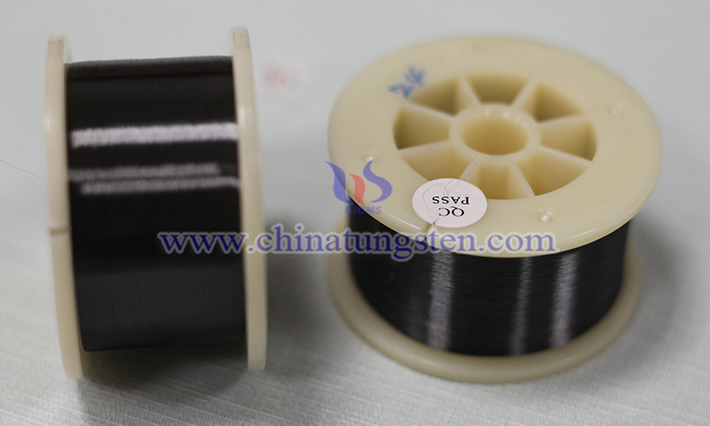

1.1 Appearance Inspection:

Use a magnifying glass or microscope to observe the surface of the tungsten wire to check for cracks, scratches, oxidation or impurities. Ensure that the diameter of the tungsten wire is uniform and there is no obvious deformation or breakage.

1.2 Dimension Measurement:

Use a high-precision micrometer or laser diameter gauge to measure the diameter of the tungsten wire to ensure that it meets the design specifications (such as 0.1mm~1mm range, depending on the application). Check whether the length meets the requirements.

1.3 Mechanical Properties:

Test tensile strength and ductility, and use a tensile testing machine to measure the breaking strength of the tungsten wire at room temperature and high temperature. Detect creep properties at high temperatures to ensure that the tungsten wire is not easily deformed during long-term heating.

2. Chemical Performance Test

2.1 Purity Analysis:

Use a spectrometer (such as ICP-MS or AES) to detect the chemical composition of the tungsten wire to ensure that the tungsten content (usually ≥99.95%) and other impurities (such as iron, nickel, and oxygen) are within an acceptable range. Excessive oxygen content may lead to high-temperature oxidation, which requires special attention.

2.2 Antioxidation:

In a simulated glass heating environment (vacuum or inert gas protection), test the oxidation degree of tungsten wire at high temperatures (such as 1800°C~2500°C). Check whether volatile oxides are generated (such as WO₃), which will affect the quality of the glass.

3. Electrical Performance Test

3.1 Resistivity Test:

Use the four-probe method to measure the resistivity of tungsten wire at room temperature and high temperature to ensure that it meets the design requirements. The resistivity of tungsten wire increases with increasing temperature, and it is necessary to verify whether its temperature-resistance curve is stable.

3.2 Power-On Heating Performance:

Power on the test in a vacuum or inert gas environment to observe the heating rate, temperature uniformity and stability of the tungsten wire. Use an infrared thermometer or thermocouple to record the highest operating temperature to ensure that it does not exceed the melting point of tungsten (about 3422°C).

3.3 Thermal Cycle Life:

Simulate actual working conditions, perform repeated power-on-off cycle tests, and record the life of the tungsten wire (such as the number of cycles before breaking or performance degradation).

4. Compatibility Test With Glass

4.1 Thermal Expansion Matching:

Measure the difference in thermal expansion coefficients between tungsten wire and glass to ensure that the glass will not crack due to thermal stress during heating and cooling. The thermal expansion coefficient of tungsten is about 4.5×10⁻⁶/K, which needs to match the glass used (such as borosilicate glass).

4.2 Chemical Reactivity:

Test whether a chemical reaction occurs in the contact area between the tungsten wire and the glass at high temperature, such as whether tungsten reacts with oxides in the glass to form compounds.

4.3 Sealing Test:

If tungsten wire is used for glass sealing (such as vacuum tubes or light bulbs), the airtightness of the sealing part needs to be tested, and a helium mass spectrometer leak detector is used to check for micro-leaks.

5. Environmental Adaptability Test

5.1 Vacuum or Inert Gas Environment:

Glass heating is often carried out in a vacuum or inert gas (such as argon, nitrogen), and the stability and volatility of tungsten wire in these environments are tested.

5.2 Corrosion Resistance:

If special glass (such as fluorine-containing glass) is involved, the tolerance of tungsten wire to corrosive gases needs to be tested.

6. Commonly Used Testing Equipment

6.1 Optical Microscope/Scanning Electron Microscope (SEM): observe surface morphology.

6.2 X-Ray Diffraction (XRD): analyze crystal structure and impurity phase.

6.3 Resistance Tester: measure electrical properties.

6.4 High Temperature Furnace: simulate heating environment.

6.5 Thermal Expansion Meter: test thermal expansion coefficient.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com