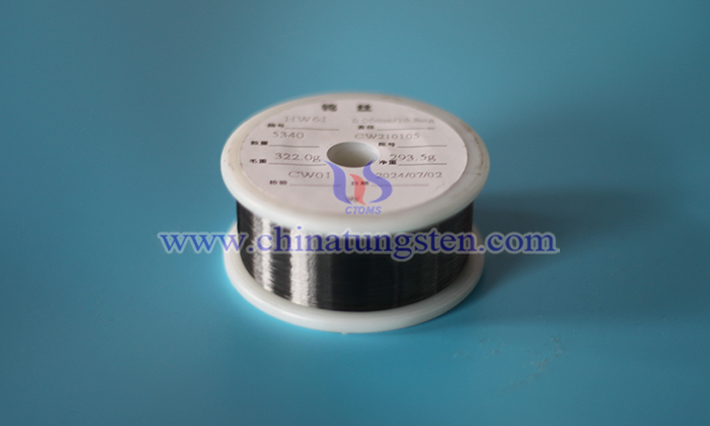

Chemical Properties of Cut-resistant Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Monday, 03 March 2025 19:44

The chemical properties of cut-resistant tungsten wire are primarily based on the chemical characteristics of tungsten metal. Tungsten, a chemical element with the symbol W and atomic number 74, is renowned for its extremely high melting point and chemical stability. Below are the key chemical properties of cut-resistant tungsten wire:

1. Chemical Stability

It exhibits high chemical inertia in normal temperature and dry environments, not reacting with water, oil, or organic solvents, making it suitable for humid or oily industrial environments.

2. Oxidation Resistance

At room temperature, a dense oxide film forms on the surface of tungsten wire, protecting the internal tungsten from further oxidation. However, at high temperatures, this oxide decomposes, and the tungsten wire reacts with oxygen to form tungsten trioxide (WO₃). Therefore, high-temperature oxidation is a limitation of its chemical properties.

3. Acid and Alkali Resistance

Tungsten wire is highly resistant to most acids and bases at room temperature: it does not readily react with strong acids (such as hydrochloric acid, sulfuric acid, and nitric acid) or strong bases (such as sodium hydroxide). This corrosion resistance allows tungsten wire to remain stable in various chemical environments.

4. Reaction with Halogens

Under high-temperature conditions, tungsten wire can react with halogens (such as fluorine, chlorine, and bromine) to form corresponding halides. This characteristic needs attention in specific industrial applications to avoid use in extreme environments containing halogen gases.

5. Reaction with Carbon

At high temperatures, tungsten wire can react with carbon to form tungsten carbide (WC). Tungsten carbide is an extremely hard compound commonly used in the manufacture of wear-resistant cutting tools.

6. Reaction with Nitrogen

In high-temperature environments, tungsten wire can react with nitrogen to form tungsten nitride (WN), which is another possible chemical change under such conditions.

7. Resistance to Environmental Stress Corrosion Cracking (ESCC)

High-purity tungsten wire has strong resistance to stress corrosion in corrosive media such as chlorides and sulfides, but impurities (such as Fe, Ni) can significantly reduce its performance.

8. Purity and Impurity Effects

Industrial-grade tungsten wire typically has a purity of >99.95%, with impurity levels (such as oxygen, carbon) controlled at <0.01% to prevent grain boundary corrosion or embrittlement.

9. High-temperature Chemical Behavior

It exhibits excellent high-temperature stability in inert gas (such as argon) or vacuum environments but may undergo slight hydrogen embrittlement in reducing atmospheres (such as hydrogen).

Testing Standards

10. Corrosion Resistance: ASTM G48 (pitting corrosion test), ISO 9227 (salt spray test);

High-temperature Oxidation: ASTM G54 (determination of high-temperature oxidation rate).

These properties enable cut-resistant tungsten wire to perform excellently in harsh environments such as high temperatures and high corrosion, leading to its widespread application in the electronic industry, filament manufacturing, and cutting tool fields.

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com