Pure Tungsten Electrodes: Key Material in the Welding Industry

- Details

- Category: Tungsten Information

- Published on Wednesday, 26 February 2025 20:24

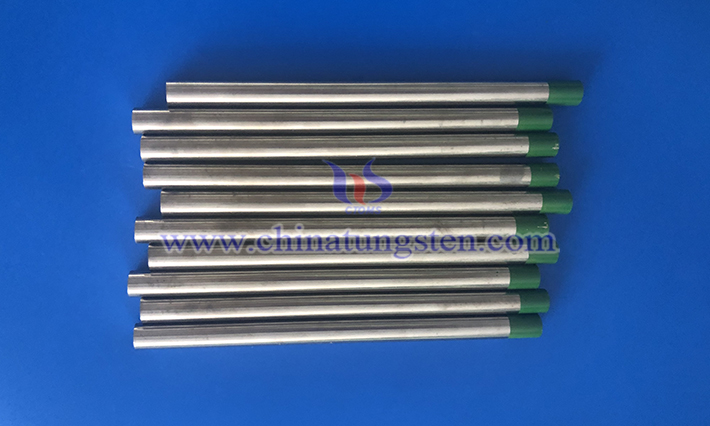

Pure tungsten electrodes, as one of the earliest electrodes used in argon arc welding, have consistently played a significant role in the welding industry. This type of electrode, characterized by its high melting point, high density, corrosion resistance, and excellent electrical and thermal conductivity, has become an indispensable key material under specific welding conditions.

Pure tungsten electrodes contain up to 99.5% tungsten. This high purity tungsten material provides the electrode with a very high electron work function but also poses challenges such as difficulty in initiating arcs and maintaining arc stability. Especially under direct current welding conditions, pure tungsten electrodes are prone to issues like arc failure or instability. To improve this situation, rare earth oxides are often added to pure tungsten to enhance its welding performance. However, despite these challenges, pure tungsten electrodes excel under alternating current welding conditions, making them commonly used as AC welding electrodes or resistance welding electrodes.

The superior properties of pure tungsten electrodes, such as low vapor pressure, low electrical resistance, low thermal expansion coefficient, and high elastic modulus, give them unique advantages when welding lightweight metals like aluminum and magnesium alloys. During AC welding, pure tungsten electrodes provide stable arcs and clean weld seams, which are crucial for ensuring welding quality. Additionally, pure tungsten electrodes have a long service life, which can help reduce welding costs to a certain extent.

It's worth noting that the application of pure tungsten electrodes is not without limitations. Due to their high electron work function, the electrode tips reach high temperatures, leading to grain growth that can affect arc stability and even shorten the electrode's lifespan. Therefore, special attention needs to be paid to the grinding and storage of pure tungsten electrodes to avoid contamination and damage. Meanwhile, because pure tungsten electrodes perform poorly under DC welding conditions, it is important to select the appropriate electrode type based on the welding conditions in practical applications.

With the continuous development of welding technology, pure tungsten electrodes are also undergoing continuous innovation and improvement. On the one hand, optimizing electrode preparation processes and adding components like rare earth oxides can enhance the welding performance and stability of pure tungsten electrodes. On the other hand, the emergence of new welding technologies has opened up new possibilities for the application of pure tungsten electrodes. For example, in automated and intelligent welding systems, pure tungsten electrodes can be combined with other advanced materials and technologies to achieve more efficient and precise welding processes.

Benefiting from the rapid development of high-end manufacturing sectors such as automobiles, aerospace, and electronics in China, there is a growing demand for high-quality, high-performance tungsten electrodes. Chinatungsten Online provides professional customized services for tungsten electrode products. Welcome to inquire by email (sales@chinatungsten.com).

- Chinatungsten Online: www.tungsten.com.cn

- CTIA GROUP LTD: en.ctia.group

- Tungsten News & Price: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com