Coolants for Machining Cobalt Alloys and CoCrMo Alloys

- Details

- Category: Tungsten Information

- Published on Wednesday, 19 October 2022 16:33

Many researchers have analyzed the effect of coolants on tool wear, cutting temperatures, and cutting forces when facing and turning cobalt alloys and CoCrMo alloys for machining surface integrity. Surface integrity is crucial for medical applications, especially for surgical implants and devices. Cobalt alloys and Co/Cr/Mo alloys machining operations typically generate residual stresses through the outer layers of the machined surface of the workpiece, and these residual stresses present a potential risk in terms of crack generation and extension and affect the corrosion resistance of surgical implants.

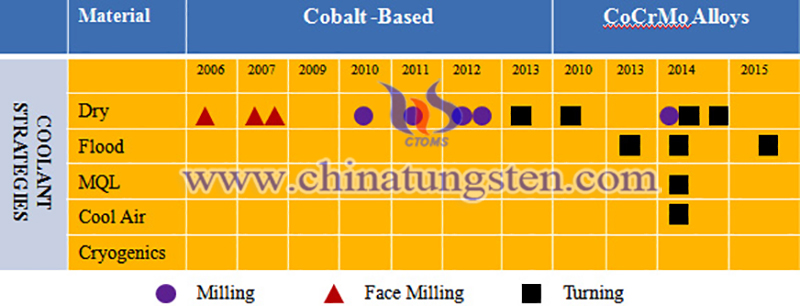

The ability of cutting fluids to eliminate heat generated by friction during machining provides better tool life, acceptable surface finishes, and better dimensional tolerances. Many researchers had used dry machining due to the adverse effects of cutting fluids, which are harmful to the environment and difficult to handle, and only recently have they begun to focus on minimizing the use of cutting fluids when machining CoCrMo alloys.

In addition, dry machining is considered to be the best alternative to cutting fluids, ultimately reducing machining costs and ecological hazards. Dry machining is also considered to be free of contamination, with no health threat to the operator, low handling and cleaning costs, no skin sensitization, and minimal machining costs. However, dry machining also has its limitations, which are mainly due to the high heat generated by friction and adhesion between the tool and the workpiece in the cutting zone.

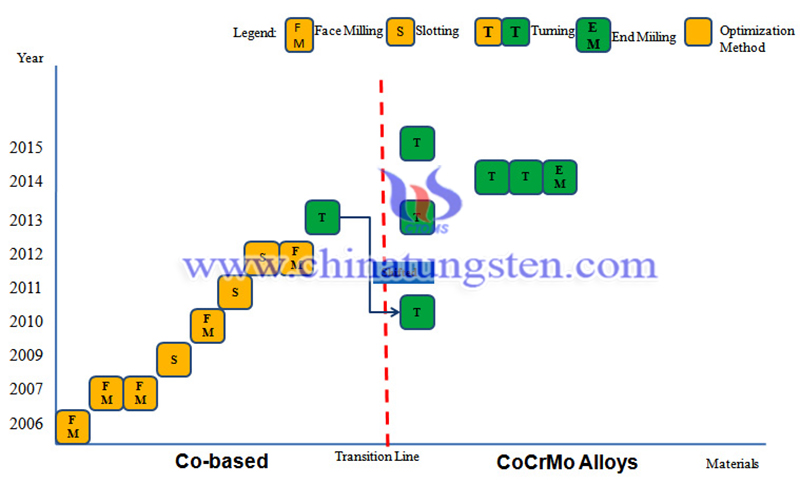

This phenomenon increases tool wear and reduces tool life. Karpuschewski et al. investigated the effect of different coolants on surface integrity when turning CoCrMo alloys with ceramic tools. They reported that emulsion and dry machining under full jet cooling had the least effect on the surface layer of Co/Cr/Mo alloys. The researchers summarized the research gaps in machining response during the past decade in machining cobalt-based and Co/Cr/Mo alloys, with many studies examining surface integrity, tool wear, and cutting forces quite extensively.

Cited paper: Zaman H A, Sharif S, Kim D W, et al. Machinability of cobalt-based and cobalt chromium molybdenum alloys-a review[J]. Procedia Manufacturing, 2017, 11: 563-570.

| Molybdenum Supplier: Chinatungsten Online www.molybdenum.com.cn | Tel.: 86 592 5129696; Fax: 86 592 5129797;Email:sales@chinatungsten.com |

| Tungsten News & Prices, 3G Version: http://3g.chinatungsten.com | Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn |

sales@chinatungsten.com

sales@chinatungsten.com