WO3 Cocatalyst Improves Hydrogen Evolution Capacity of ZnCdS

- Details

- Category: Tungsten Information

- Published on Wednesday, 06 October 2021 11:52

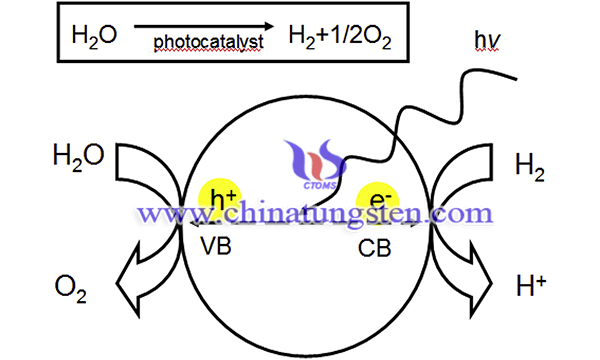

With the intensification of global warming and fossil energy crisis, people are paying more and more attention to the search for renewable clean energy. Solar energy and hydrogen energy are a kind of sustainable energy. Photocatalytic technology can convert solar energy into hydrogen energy. In recent years, the use of semiconductor materials to split water to produce hydrogen under light has always been a research hotspot.

Zinc cadmium sulfide (ZnCdS) ternary solid solution possesses the merits of both CdS and ZnS as well as high photocorrosion resistance and high visible light response, and thus is a very promising photocatalyst. However, it has the drawback fast recombination rate. The most commonly-used method to overcome this is to load a cocatalyst to ZnCdS. Tungsten trioxide (WO3) is a very stable photocatalyst under acid conditions and is an environmental-friendly semiconductor.

In order to enhance the hydrogen generation ability of ZnCdS, WO3 cocatalyst has been combined with it. At the same time, WO3 replaces precious metals with high cost and limited source, reducing costs and making it possible for large-scale applications. WO3 cocatalyst has been applied to improve the hydrogen evolution capacity of ZnCdS. The WO3/ZnCdS material shows a higher photocatalytic hydrogen production activity. The synthesis of WO3/ZnCdS photocatalyst is as below:

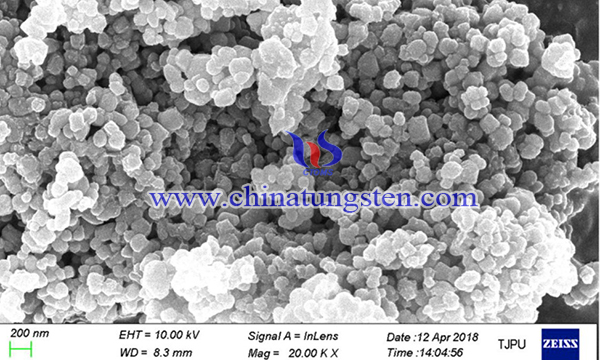

The reagents used in this experiment were of analytical grade without further purification. The ZnCdS photocatalyst was prepared by hydrothermal method. The specific preparation process was as follows: 10 mmol Zn(Ac)2 was dissolved in 10 mL deionized water, 10 mmol Cd(Ac)2 was dissolved in 10 mL deionized water, 25 mmol thioacetamide was dissolved in 10 mL deionized water, and they were all stirred at a constant speed for 5min. Then added Cd(Ac)2 solution and thioacetamide solution to Zn(Ac)2 solution, and added 10 mL deionized water after mixing, stirred at a constant speed for 10min. 40 mmol NaOH dissolved in 10 mL deionized water, stirred at a constant rate for 5 min and added dropwise to the above mixture. The mixture was stirred at a constant rate for 40 min to form a homogeneous solution, transferred to a 100 mL stainless steel polytetrafluoroethylene autoclave, placed in an oven and reacted at 180 °C for 24 h. After completion of the reaction, the mixture was cooled to room temperature, and the product was transferred to a centrifuge tube and washed by water for 3 times, and dried in a vacuum oven at 80 °C for 10 h, and then obtained ZnCdS powder. Take 35 wt% WO3/ZnCdS as an example: 0.05g ZnCdS and 0.023g ammonium metatungstate were put in a small magnetic boat, placed it in the tube furnace with N2 and raised it to 500 °C at a heating rate of 10 °C/min. After reacting for 2 h, the mixture was washed with water and centrifuged, and dried under vacuum.

In conclusion, WO3/ZnCdS compound photocatalysts were synthesized from a temperature-programmed reduction method. The result revealed that the hydrogen yield was the highest when the concentration of the cocatalyst WO3 was 35 wt%. The hydrogen production activity of the 35 wt% WO3/ZnCdS was the highest to 98.68 μmol/mg, about 9.6 times that of pure ZnCdS (10.28 μmol/mg). After 5 cycles, it yet had high repeatability and preserved high hydrogen production activity after 100 h of photocatalytic tests.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com