Growth of Tungsten Trioxide on Carbon Nanowalls

- Details

- Category: Tungsten Information

- Published on Friday, 17 September 2021 00:05

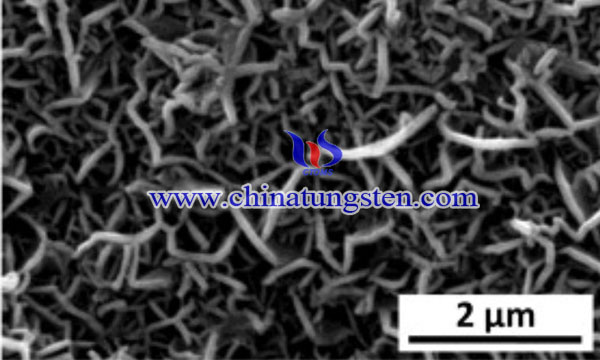

Carbon nanowalls (CNWs) have a wide range of applications such as supercapacitors, Sensors and, etc due to its structure, electrical, optical and mechanical properties, CNWs are also named as vertical graphene nanosheets. They have a three-dimensional structure and represent a kind of maze (labyrinth-like) graphene nanosheets with vertical orientation on the surface, which can be freely Perpendicular to the substrate. Unlike carbon nanotubes, one of the characteristics of CNW is that their synthesis does not require a catalyst. Therefore, they can be synthesized on substrates of various materials, such as metals (stainless steel, Pt, Ti, Cu, Ni, Mo, Zr, Hf, Nb, W) semiconductors (Si) and even insulators (Al2O3, quartz). Tungsten oxide (WO3) is an important n-type semiconductor and it is a promising material to combine with carbon nanowalls.

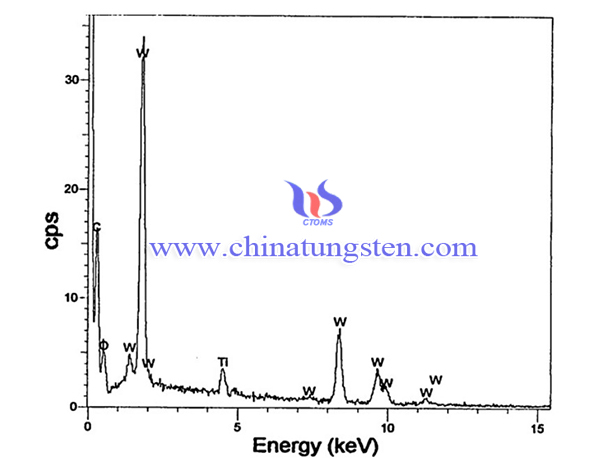

Thus, doping of tungsten oxide onto carbon nanowalls is conducted by chemical vapor deposition (CVD) technique. The growth of tungsten trioxide on carbon nanowalls is based on heating a thin tungsten filament in a vacuum chamber under controlled conditions without the presence of catalyst. The synthesis of WO3/CNWs structure is as follows:

Carbon nanowalls are prepared by plasma-enhanced hot filament CVD system deposition on Ti substrates; they are used as templates for the growth of tungsten oxide. The hot filament is a coiled tungsten wire with a diameter of 1 mm, which is heated by a 16 V AC power supply. When the distance between the substrate and the hot filament is fixed at 8 mm. During the deposition process, hydrogen and methane enter the CVD reaction chamber at flow rates of 6 and 18 sccm, respectively. Then a negative substrate bias of 100 V generated by a DC power supply is set between the hot filament (anode) and the substrate holder (cathode). The pressure of the system is maintained at approximately 25 Torr, and the typical deposition time lasts 30 minutes. When the deposition process is complete, the methane flow is stopped, and the film is cooled to room temperature in the presence of hydrogen by slowly reducing the power.

The same hot filament CVD system uses the carbon nanowall as a template for growing tungsten oxide. In the absence of feed gas and reactants, the production of tungsten oxide is based on the oxidation of tungsten filaments by oxygen. The carbon nanowall is placed vertically at a controlled distance of 5 mm relative to the tungsten wire. When the system pressure is adjusted to about 20 Torr, the tungsten wire is heated at 4 V. After a typical heating time of 5 minutes, allow the product to cool to room temperature naturally.

In summary, the growth of tungsten trioxide on carbon nanowalls is based on heating a thin tungsten filament in a vacuum chamber under controlled conditions without the presence of catalyst. The process is simple and cost-effective. The WO3-CNWs structure reveals an obvious photoresponse behavior.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com