Nanosized Tungsten Bronze by A Thermal Decomposition of Ammonium Metatungstate

- Details

- Category: Tungsten Information

- Published on Sunday, 01 August 2021 04:42

The near-infrared radiation (NIR) absorbers are of fundamental significance in several fields of applications in optical sensors, photothermal energy converter, imaging, NIR stealth cloak, and smart windows.

Smart windows coated with NIR absorbents can dynamically and reversibly adjust the amount of solar radiation entering a building in response to external stimuli, providing a promising solution for reducing building’s energy consumption. In addition, NIR absorbents are useful materials for solar collectors and optical filters. Tungsten bronzes (MxWO3) is promising NIR absorbents, owing to their distinctive electrical and optical properties, which depend on their stoichiometric composition.

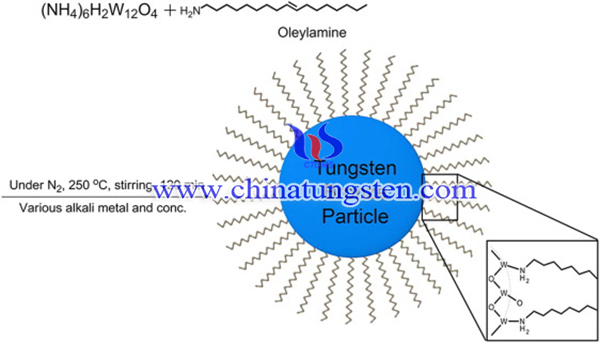

Recently, it is reported that nanosized quaternary tungsten bronze has been successfully produced by a thermal decomposition of ammonium metatungstate. The as-prepared product had an average diameter of about 30 nm and exhibited a shielding property of approximately 97% of near-infrared radiation. The preparation process of quaternary tungsten bronze is as following steps:

Initially, A slurry was produced by adding 0.2956 g (0.1 mmol) of ammonium paratungstate (AMT) to 20 mL oleylamine (>70%) with magnetic stirring. Then, stoichiometric amount of cesium hydroxide monohydrate (CsOH·H2O) was added and stirred for 1 h. Move the solution to a three-neck round-bottomed flask connected to a reflux condenser. The atmosphere in the reactor was replaced with nitrogen gas by purging for an hour, following which the flask was heated at 250 °C under stirring while maintaining the nitrogen atmosphere. After 2 h the reaction was observed to be complete and the reaction mixture was allowed to naturally cool down to room temperature. The precipitate was collected by using centrifugation for 15 min at 8000 rpm, after which it was washed twice with acetone to remove the excess oleylamine. The collected precipitate was then magnetically stirred with acetone for 2 h to re-disperse the agglomerated nanoparticles, after which it was dried at room temperature. Finally, the product was obtained.

In summary, nanosized tungsten bronze has been successfully produced by a thermal decomposition of ammonium metatungstate. The quaternary tungsten bronze had an average diameter of about 30 nm and exhibited a shielding property of approximately 97%.

- AMT Manufacturer & Supplier, Chinatungsten Online: ammonium-metatungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com