Tungsten Trioxide Gas Sensor for NO2 Detection

- Details

- Category: Tungsten Information

- Published on Sunday, 01 August 2021 04:04

Nitrogen dioxide (NO2) gas is a kind of toxic gas, which is mainly produced by the exhaust gas of burning fossil fuel. Breathing air with a high concentration of NO2 can irritate airways in the human respiratory system. It is reported that the short-term exposure limit of NO2 gas for human body is 1 ppm for 15 min. Thus, gas sensing detection of NO2 gas is very important to protect environment and protect human health. There are drawbacks of low sensing response and low decetion efficiency within common sensors.

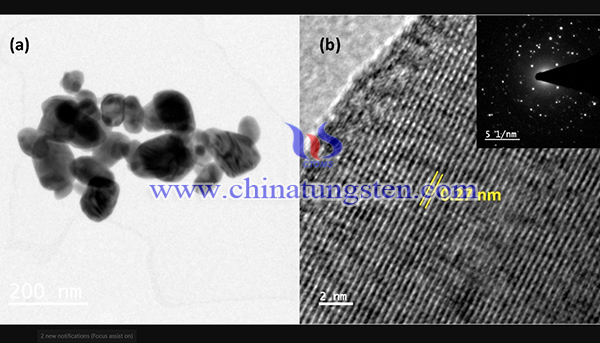

Tungsten trioxide (WO3) nanosized film has been gained extensive interest for its high gas sensing response on NO2. WO3 is an n-type semiconducting metal oxide which has wide band gap of (2.6–3.3 eV) and the crystal structure property of WO3 material is temperature dependent and shows triclinic, monoclinic, orthorhombic and tetragonal structure at different temperature ranges.

In order to overcome these disdavantages, tungsten trioxide (WO3) gas sensor has been successfully fabricated for NO2 detection, and the as-prepared sensor reveals the highest response of 20.36 for 100 ppm NO2.The synthesis process of is as following steps:

500 mg of WO3 powder was first mixed with 0.4 ml of terpineol anhydrous, 50 mg of methyl cellulose and 0.2 ml of methanol at room temperature and it was ultrasonically stirred for 60 min to form a homogeneous viscous liquid paste, which was then drop-casted using dropper on the cleaned IDE devices. Then annealing furnace was used to anneal the films at 500 °C for 2 Hr. in N2 ambient to evaporate organic solvents and binder to obtain good adherent WO3 film.

Initally, 2-inch p-type (<100> orientation) silicon wafer was cleaned using standard RCA procedure. Then, 200 nm SiO2 was grown using dry oxidation as an insulation layer. Dehydration of wafer was carried out at 90 °C for 3 min. Lift-off-resist (LOR) was spin coated on the wafer at 300 rpm for 15 s and then at 5000 rpm for 45 s, after that it was prebaked at 150 °C for 5 min. Positive photoresist (PPR) S-1813 was spin coated at 300 rpm for 15 s and then 3000 rpm for 30 s and after that, it was postbaked at 90 °C for 3 min as shown in Fig. (1 b). To transfer the IDE pattern from the designed mask, the wafer was exposed to UV light using DSA-EVG620 at a constant dose of 80 mJ cm−2. Afterwards, the pattern was developed in developer solution (MF319) for 30 s then rinsed using isopropyl alcohol (IPA) and dried at N2 gas as shown in Fig. (1 c). A thin layer of Cr/Au (20 nm/80 nm) was deposited using thermal evaporator as shown in Fig. (1 d), whereas Cr layer produced good adhesion between gold and SiO2. Finally, in the lift-off technique, the processed wafer was kept in PG removal solution for 12 Hr. to remove resist and only required Cr/Au pattern remained. Finally, the WO3 film was drop-casted on fabricated IDE structure. Tungsten trioxide (WO3) gas sensor was synthesized.

In summary, tungsten trioxide (WO3) gas sensor has been successfully fabricated for NO2 detection the surface morphology of WO3 film showed good roughness and nanoporous structure which enhanced the gas sensing properties. Addition of IDE device into the WO3 sensor increases the overall sensitivity and provides extremely high response-recovery time. The sensor exhibited the highest sensing response of 20.36 towards 100 ppm NO2 at an operating temperature of 200 °C. WO3 sensor showed an excellent response-recovery time. WO3 sensor showed a lower detection limit of 5 ppm NO2 gas at 200 °C.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com