The W–As Composite Nanopowders Utilizing Ammonium Paratungstate as Raw Material

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 05:43

Tungsten powders are produced from wolframite or scheelite ores through the intermediate product of ammonium paratungstate (APT) or ammonium metatungstate (AMT). The existence form of As is FeAsO4 in scheelite ores and its weight percentage is amounts to 0.03–0.3%. Arsenic is removed as an injurious impurity in the preparation process of AMT (or APT). However, this process is very complicated and there is still about 0.001 wt% of As remained in the AMT (or APT).

It is discovered that arsenic could refine tungsten powder grains, makes it possible to use As in the scheelite ores to produce nanocrystalline tungsten powder by hydrogen reduction. keep and utilize the arsenic in scheelite ores to produce nanocrystalline W powders by hydrogen reduction tungsten oxide method. The W–As composite nanopowders have been produced using ammonium paratungstate as raw material.

The synthesis method of W–As composite nanopowders is as below: Commercially available ammonium metatungstate (AMT, purity >99.9%, mean particle size: 7.8 μm), ammonium paratungstate (APT, purity >99.9%, mean particle size: 37.5 μm) and arsenic (As) were purposely used as the raw materials. As-doped AMT (or APT) precursors were synthesized by a solution chemical process through a nitric acid solution (HNO3). The details of the precursor synthesis were described as following: firstly, arsenic was dissolved into an aqueous solution of 65–68 wt% nitric acid; then AMT (or APT) was added into the mixture solution of nitric acid and arsenic; lastly, the solution was dried at 80 °C in oven for 12 h to remove moisture and homogeneous mixture precursors were prepared. Four composite precursors of AMT, AMT–0.01%As, AMT–0.1%As, AMT–1%As (weight ratio of AMT:As equal 100:0, 99.99:0.01, 99.9:0.1 and 99:1, respectively) were synthesized by the above steps, respectively.

Thermal processing (calcination and reduction) of the precursors was carried out in a tube furnace. The four AMT–As composite precursors were calcined at 600 °C in non-flowing air for 2 h to form As doped WO3 composite powders, respectively. Subsequently, the As doped WO3 composite powders (3.0–4.0 g) were filled in an alumina ceramic boat with a size of 60 × 30 × 14 mm. The reduction process was carried out in a tube furnace at 800 °C for 3 h and cooled to room temperature in a flowing hydrogen (dew point: −40 °C), resulting in four samples of As doped W powders were prepared by this process and noted as W, W–0.01%As, W–0.1%As and W–1%As, respectively. All heating rate was controlled at 5 °C/min.

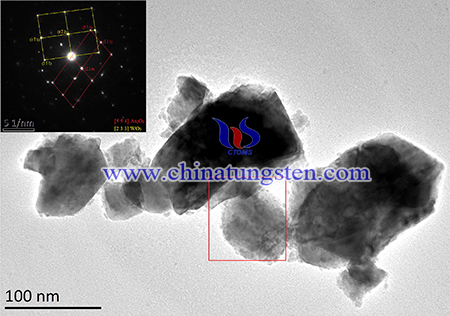

In summary, the W–1%As composite nanopowders with WAs2/W core–shell structured were prepared by AMT–1%As as raw materials combined with hydrogen reduction at 800 °C for 3 h. The W–1%As composite powders were uniform with the diameters about 80 nm. The WAs2 intermediate phase existed in the interior of tungsten grains and played an important role as heterogeneous nucleation core in the process of W nucleation, as a result of increasing the number of the nucleation.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com