ELM Technique Applied in APT Production with Less Environmental Effect

- Details

- Category: Tungsten Information

- Published on Thursday, 08 July 2021 07:33

Ammonium paratungstate(APT)is white crystalline salt, with the chemical formula (NH4)10(H2W12O42)•4H2O. It is the most important raw material for most of tungsten products. Intermediates such as tungsten trioxide, tungsten blue oxide, tungstic acid, can be obtained from APT, either by thermal decomposition or chemical conversion.

Solvent extraction (SE) and ion exchange (IE) are the two common synthesis method of APT. In the SE method, the raw sodium tungstate (Na2WO4) solution from tungsten ore firstly needs to eliminate P, As, and Si by adding HCI and MgCl2, and Mo by adding Na2S, which is a pollutant. Further, the acidic waste water needs to be treated and the residual Win it needs to be recovered. In the IE method, although P, As and Si do not need to be eliminated, yet Mo is still needed. In the conventional production of APT, a quantity of wastewater has been produced and therefore has brough a lot negative environmental effect. Thus, a synthesis method with less environmental effect is in need.

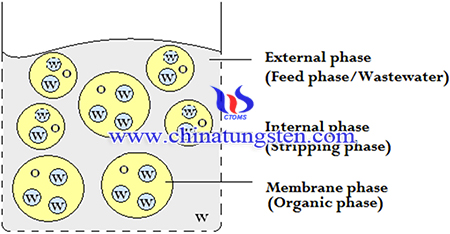

Emulsion liquid membrane (ELM), is considered as a simple, effective method to produce APT. A new process has been described as follows: The alkaline feed of crude Na2WO4 solution from the caustic fusion of black tungsten ore was neutralized to a pH value near 9 to remove Si as routine, then the resulting feed was directly used as the external aqueous phase without eliminating P, As and Mo.

Through a single stage batch liquid membrane process at room temperature for 5 rain under optimum operation conditions obtained by an orthogonal test, APT directly crystallizes in the internal aqueous phase with 99.87% yield and the quality attained was the first grade of a national standard; meanwhile the pH value of the effluents was lowered to 6-7 in itself suitable for direct discharge.

In conclusion, Synthesis method of ammonium paratungstate (APT) crystals through Emulsion liquid membrane (ELM technique) has simple process, less pollution and high yield. This method has a high efficiency of 99.87% yield. Furthermore, less environmental pollutants had been produced in the synthesis procedure compared to the traditional methods.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com