WO3 Photoanode Fabricated with Ammonium Paratungstate for Photoelectric Removal of Urine

- Details

- Category: Tungsten Information

- Published on Friday, 05 February 2021 20:35

Urine is one of the most gravimetric nitrogen (N) carriers in human excrement and contributes 80% of the nitrogen and 10% of the COD load in urban sewage in spite of accounting for only one percent of domestic wastewater.

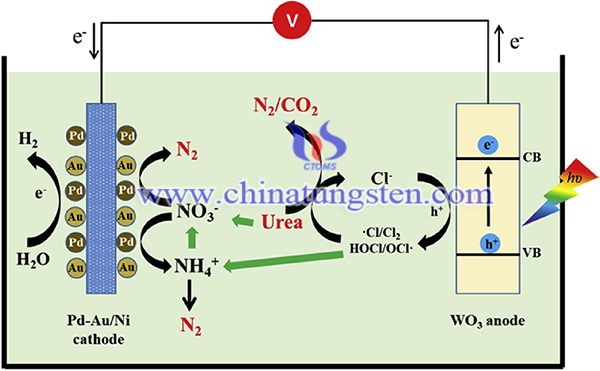

Thus, an efficient photoelectric degradation system targeting urine removal in sewage was designed and to investigated its efficiency. Tungsten trioxide (WO3) was prepared using ammonium paratungstate (APT) and used as the photoanode to initiate Cl under illumination, and a cathode with Pd/Au modified porous metal was designed to effectively reduce N2 for the goals of cycle removals of urine.

The photodegradation design for urine is as below:

1. Preparation of WO3 photoanode and Pd/Au/PM cathode

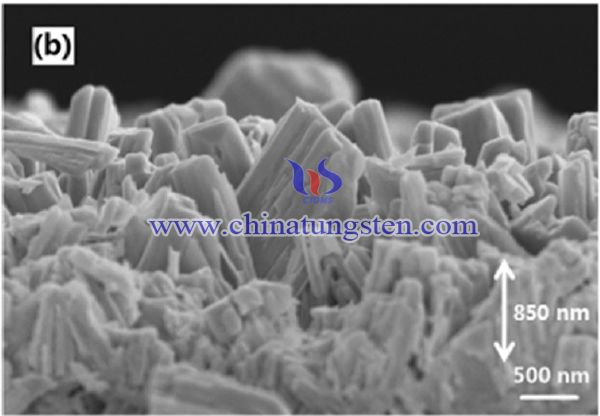

The purchased F-doped tin oxide (FTO) substrate (13 Ω cm−1) was cut into 25 mm × 50 mm slides and washed under ultrasonication with acetone and deionized water for 30 min. The WO3 photoanode was prepared via a hydrothermal method [16]. In a typical process, 1 g of ammonium paratungstate (NH4)10(H2W12O42)radical dot4H2O was dissolved in 96 ml deionized water. 2 ml of concentrated HCl was added (approximately 5M) to the above aqueous solution and stirred for 1 h. Then, 2 ml of H2O2 was added and stirred vigorously for 1 h to dissolve the tungstic acid. After that, the solution was transferred to a Teflon-lined autoclave and a FTO substrate was placed at an angle to the wall of the Teflon liner with the conductive side down. The hydrothermal synthesis was conducted at 400 °C for 2 h and naturally cooled down. Finally, the as-prepared sample was rinsed and dried, followed by calcination at 500 °C in air for 2 h.

The modified cathode was prepared by co-electrodeposition of Pd and Au using potentiostatic technique. The porous metal sheet, Pt foil and a saturated calomel electrode (SCE) were used as the working electrode, counter electrode and reference electrode, respectively. The deposition was conducted in the aqueous solution composed of 0.05 mM PdCl2 and 0.05 mM HAuCl4 using cyclic voltammetry method at 0.8 V for 800s. Then, the Pd/Au/PM was cleaned with deionized water and subsequently dried at 60 °C under vacuum.

2. Degradation of urea/urine

A WO3 anode (25 × 50 mm, FTO substrate) and a Pd/Au/PM cathode (20 × 40 mm, porous metal substrate) in Fig. S1 constituted single photoelectrolysis cells (shape: cube, working volume of 50 cm3) with an Ag/AgCl/Sat as the reference electrode. All photoelectrochemical experiments were carried out under the potentiometric conditions and driven by the CHI electrochemical analyser (CHI 660C, Chenhua Instrument Co., Ltd., China). A 350 W Xe lamp with an AM 1.5 filter was chosen as a light source. All experiments were carried out under visible light (light intensity, 100 mW cm−2) with illuminated area of 16 cm2 in the reactor, moderate stirring with applying external constant potential. 50 cm3 of synthetic wastewater was used, containing 30 mg L−1 urea, 0.05 M Na2SO4 and a constant concentration of NaCl (to support Cl−, 0, 0.025, 0.05, 0.075, 0.1M). A pH buffer was applied in all the experiments to prevent pH drifting.

In conclusion, an efficient photoelectric degradation system targeting urine removal in sewage was designed and to investigated its efficiency. Tungsten trioxide (WO3) was prepared using ammonium paratungstate (APT) and used as the photoanode to initiate Cl under illumination, and a cathode with Pd/Au modified porous metal was designed to effectively reduce N2 for the goals of cycle removals of urine. The thickness of the WO3 films remained almost the same at 850 nm. WO3 nanoplate has crystalline phase and an absorption wavelength of 450 nm. The result showed an excellent removal efficiency (99.37%) and TOC removal efficiency (50.91%). This work sheds light upon a new economical, efficient, and environment-friendly means of urine sewage treatment.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com