Testing Method of Sag of Tungsten Wire

- Details

- Category: Tungsten Information

- Published on Tuesday, 09 February 2021 10:43

The testing method of sag of tungsten wire is processed according to Chinese standard of GB 4105-83, which is suitable for the diameter of Ø0.35~1mm.

1.0 Principle

Under the condition of high temperature and self-weight, the strength and crystal structure of tungsten hanging wire is sagging. The sagging value is related to the self-weight of wire itself, and the W wire high temperature stability can be confirmed.

2.0 Preparation of testing sample

2.1 Cleaning

Clean the wire in NaOH fluid with 20% concentration, then water, to the condition that the surface of graphite layer is removed and the surface is bright. After that, dry the wire.

2.2 Forming

Straight the wire by hand and shape into hairpin like on a rod with a diameter is triple of W wire, the legs after forming should be on the same level. Wire with larger diameter can be heated to form the shape, the heating length should be less than the hairpin length 20%.

3.0 Testing Equipment

3.1 Heating Equipment

The heating equipment includes electricity charged molybdenum heating chuck, copper electricity rod and cover with water cooling system. The two chucks can be rotating 180°.

3.2 Hydrogen Supply System

This system includes conveying pipelines, flow meters, control switches, purification equipment and testing instruments.

Hydrogen is used as the protective gas for the sagging experiment, and its dew point must be lower than -45°C.

3.3 Measuring Instruments

An altimeter with a reading accuracy of 0.05mm is used to measure the sagging value of the sample after heating.

3.4 Recording Instrument

Use 0.5 grade precision electric meter to measure and control test current.

3.5 Power Supply and Regulation

Adopt a regulated power supply, and use a thyristor voltage regulator for voltage regulation.

4.0 Test procedure

4.1 Shape

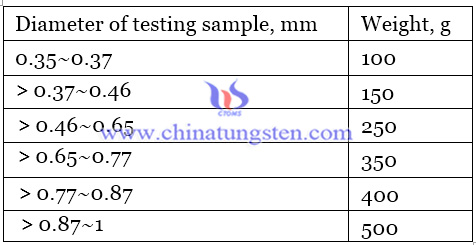

Clamp the sample on the molybdenum chuck, the tip of the hairpin is vertically downward, and the length of the heated part of the hairpin (the exposed length from the chuck to the top) is 100mm. The distance between the ends of the hairpin's legs is 12mm. Hang the corresponding weight on the hairpin according to the following table.

Put down the cover, and pass the purified hydrogen flow with a flow of 8L/min, and pass the cover and the electrode with cooling water in an appropriate amount. After the air is removed, the temperature is increased to 65% of the fusing current of the sample within 1 min, and the temperature is kept at this current for 1 min, and then the temperature is lowered.

Lift the cover, remove the weights, and rotate the two chucks 90° along the horizontal axis to make the sample horizontal, and the two legs of the sample form a horizontal plane.

4.2 Test

Use an altimeter to accurately measure the vertical height of the sample tip as the initial value h1. Put down the bell to purge the air. Then energize, heat up to 80% of the fusing current within 1 min, and keep it at this temperature for 5 min. Then cool down, power off, cool down, and open the bell. The height of the measurement sample is the end value h2.

5.0 Test results

5.1 Sagging value calculation

The sagging value is expressed in millimeters of the difference between h2 and h1.

5.2 Three tests are made for each sample, and the three test results are included in the test report, and the value is accurate to two decimal places.

6.0 Test report

The sample report should include the content of standard, manufacturer's name, batch number, size and sag value of tungsten wire.

- Tungsten Metals Manufacturer & Supplier, Chinatungsten Online: www.tungsten.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com