Ammonium Paratungstate Applied in Production of Hexagonal Tungsten Trioxide Microspheres

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 November 2020 01:21

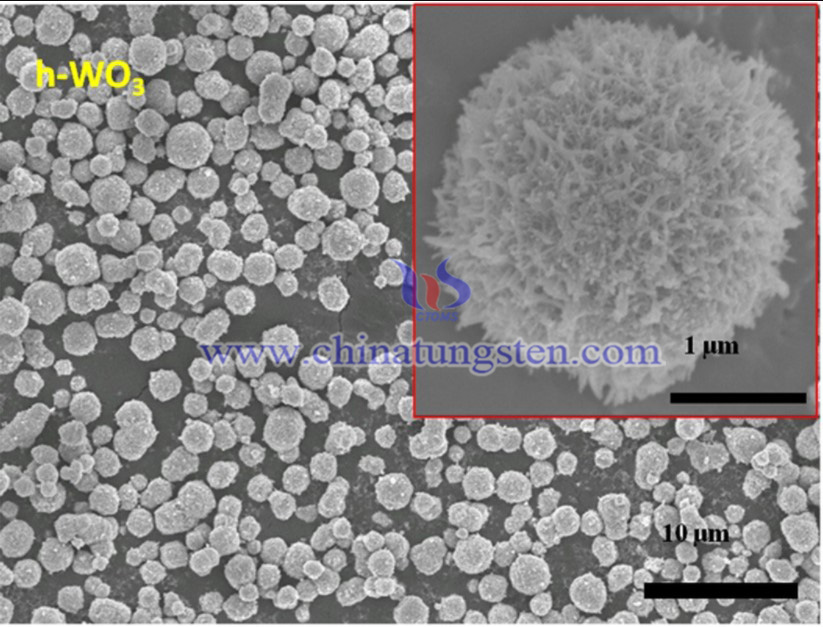

Ammonium paratungstate (APT) has been used as precursor material in production of Hexagonal tungsten trioxide (h-WO3) microspheres by hydrothermal synthesis. The as-prepared product showed significant catalytic activity in the hydrogenation of styrene under mild environment.

The main catalysts for hydrogenation reactions are supported noble-metal catalysts. The properties of the solid support on which the noble metal is dispersed significantly affect the catalytic activity and selectivity of the reaction, and the catalyst durability, because of the interactions between the support and the active phase.

However, most of these supports have one or more disadvantages such as complexity or high cost, adverse environmental effects, and poor catalytic activity or stability. It is therefore necessary to develop more efficient supported catalysts.

The fabrication method is as below:

APT, Na2WO4, hydrochloric acid, palladium chloride, ascorbic acid, styrene, ethylbenzene, and biphenyl were employed as precursor materials.

APT (2.5355 g) and deionized (DI) water (65 mL) were added to a conical flask. HCl solution (4 mol/L, 2 mL) was added dropwise under vigorous stirring for 1.0 h. The resultant solution was transferred to a Teflon-lined stainless-steel autoclave of capacity 100 ml. The autoclave was sealed, heated to 100 °C, kept in an isothermal state for 12.0 h, and then cooled to room temperature. The product was collected by filtration, washed three times with DI water, and dried at 80 °C for 24.0 h.

The Pd/h-WO3 catalyst was prepared as follows. h-WO3 microspheres (0.5 g) were added under constant magnetic stirring to a mixture of ethanol (40 mL) and DI water (60 mL) in a three-necked flask equipped with a condenser. The flask was heated in an oil bath preheated to the boiling temperature and the temperature was maintained for 1.0 h. The slurry was cooled to room temperature, followed by rapid injection of PdCl2 solution (0.02 mol/L, 2.34 mL), and stirred vigorously for 1.0 h. Ascorbic acid solution (0.1 mol/L, 1.88 mL) was added dropwise to the slurry and stirring was continued for 0.5 h. The mixture was then centrifuged. The solid was washed with ethanol, dried at 80 °C for 24.0 h, and collected for catalytic evaluation.

In conclusion, hydrothermal temperature and molar ratio of the precursor materials were two elements that significantly influence the phase composition. After comparison of the properties of h-WO3 microspheres grown under various temperature and molar ratio. We found that pure-phase h-WO3 microspheres were fabricated at a molar ratio of APT:HCl = 1:9.6 and a temperature of 100 °C. They were used as a support for a Pd catalyst, which gave a high catalytic performance in the hydrogenation of styrene. The TOF value of the prepared Pd/h-WO3 reached 3050 h−1, and the recycling performance of the catalyst proved that it had excellent recyclability.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com