Ammonium Paratungstate Applied in WO3/Carbon Nanotubes

- Details

- Category: Tungsten Information

- Published on Wednesday, 18 November 2020 01:21

Solid acid catalysts play a significant part in chemical and petroleum industries in hydrocarbon conversion reactions required in octane enhancement processes, such as cracking, isomerization and alkylation, which can form highly branched isoparaffins. Such reactions need strong or moderate acid catalysts. However, halide-type solid acids have a great negative effect on environment. Tungsten oxides supported on oxide carriers have been considered as a more environmental-friendly substitute. Therefore, it has been well studied to be catalysts for hydrocarbon isomerization processes.

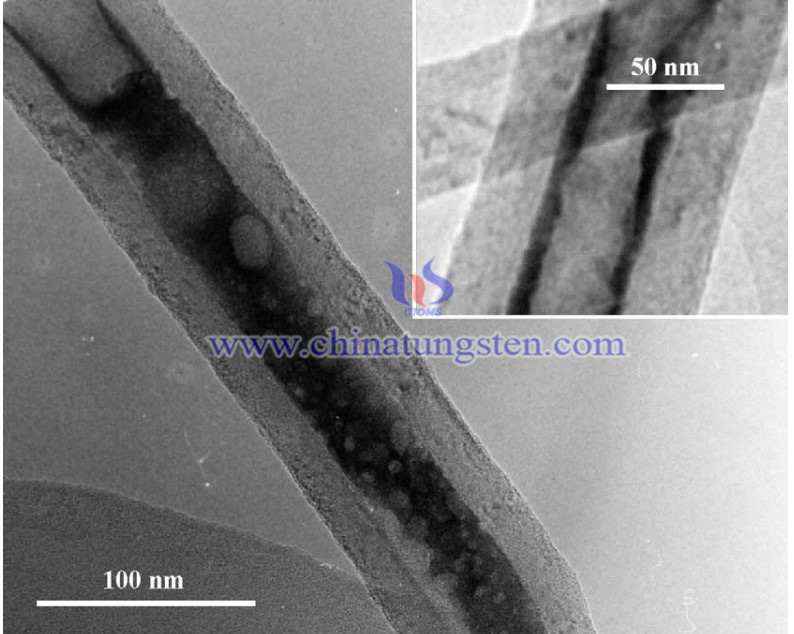

Carbon nanotubes (CNTs) have been research hotspot in the last ten years owing to its possibilities to be catalyst support and peculiar behaviors in terms of conversion or selectivity, which were attributed to specific active-phase-support interaction, limitation of mass transfer phenomena problems and/or to the existence of confinement effects inside CNTs.

High-efficiency tungsten trioxide/carbon nanotubes (WO3/CNTs) has been produced where ammonium paratungstate has been applied as precursor material. The experimental procedures are in following two steps:

(a) Precursors and Synthesis

Open multi-walled CNTs with inner and outer average diameters of 40 and 80 nm, and lengths up to about 200 μm. They had a non-microporous specific surface area of 25 m2/g obtained by BET measurement using N2 at LN2 temperature. Deposition of tungsten was performed by wet impregnation of the bare CNTs with an aqueous solution (20 mL) of ammonium metatungstate pentahydrate, (APT), at pH close to 5. The CNTs were added to the precursor salt aqueous solution kept under vigorous stirring at 80 °C for 20 min before the slow evaporation of the solvent at room temperature. The resulting material was further dried overnight at 120 °C. The WO3 content was taken at 4, 17 and 30 wt.% relative to the total weight of catalyst. The dried materials were finally calcinated at 350 °C for 2 h. Comparison was made with a WO3 (25 wt.%)/ZrO2 reference catalyst prepared following the same procedure and using commercially available monoclinic ZrO2 supplied by Johnson Matthey [16]. Catalytic performances were reported in terms of specific rate of hydrocarbon transformation expressed in mol/s/(g of WO3), isomerization selectivity and stability as a function of time.

(b) Characterization and Analysis

The as-synthesized product was characterized by X-ray diffraction (XRD), transmission electron microscopy (TEM), temperature-programmed reduction (TPR) and X-ray photoemission spectroscopy (XPS).

To sum up, the WO3/CNT materials exhibited monofunctional acidic skeletal isomerization properties with very high (100%) skeletal isomerization selectivities even at high conversion levels, confirmed by the fact that they are only active for olefin reactions but exhibit no activity toward saturated reactants.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com