Synthesis of Ammonium Paratungstate (APT) From Double Ammonium-Sodium Paratungstate

- Details

- Category: Tungsten Information

- Published on Wednesday, 09 September 2020 11:54

The conventinal autoclave soda leaching is a mature method for treating tungsten concentrate, where tungsten concentrate reacts with sodium carbonate to produce sodium tungstate. And finally through ion exchange and evaporative crystallization, ammonium paratungstate (APT) was manufactured. However the mass waste water is produced during the process.

Double ammonium-sodium paratungstate (DASP) is a complex salt of APT and sodium paratungstate and that the Na content in DASP is only about 1.40%, implying that DASP could be an intermediate to preliminarily separate tungsten from Na2WO4-Na2CO3 solution, and most of the Na2CO3 in the spent liquid can be returned to the leaching process of tungsten concentrate. If DASP can be readily transformed into qualified APT, economic circulation of sodium carbonate in the autoclave soda leaching method is most likely to be achieved.

A synthesis process of ammonium paratungstate (APT) from double ammonium-sodium paratungstate has been invented, the specific process are as follows:

- Preparation of DASP

80 mL Na2WO4-Na2CO3 solution (q(WO3) = 150 g/L, q(Na2CO3) = 130 g/L) and 20 mL (NH4)2CO3 solution (q((NH4)2CO3) = 300 g/L) were put into a sealed reactor with a stirring rate of 200 r/min and a specified CO2 pressure. After reaction at a preset temperature, the resultant slurry was filtrated and washed with 100 g/L ammonium bicarbonate solution, the obtained cake was dried at 100C for 12 h, and the WO3 concentration in filtrate was determined.

- Transformation of DASP to APT

DASP, eight zirconia ball (d = 8 mm), and (NH4)2CO3/(NH4)2SO4 were put into a 150 mL steel bomb. The sealed bomb was immersed in glycerol at a preset temperature and rotated for a certain time. After reaction, the transformation product was washed by agitating magnetically in 100 g/L ammonium bicarbonate solution and subsequently filtered and dried at 100C for 12 h.

- Analytical Methods

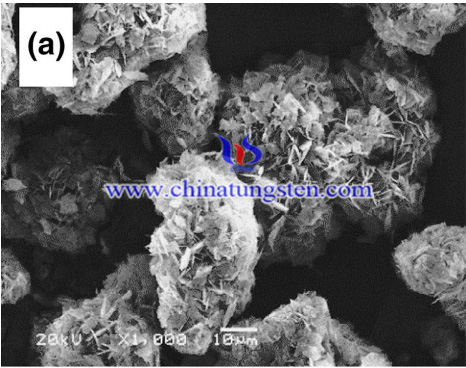

WO3 concentration in solution was determined by thiocyanate spectrometry with spectrophotometer SP-752. The Na content in DASP was analyzed by flamephotometer AP1500, while the Na and S contents in APT were detected by x-ray fluorescence with a D8-Advance(Japan). The phase and morphology of solid products were determined by x-ray diffraction analyzer (Cu-Ka, 8 min1 ) with a Bruker D8-Advance (Germany) and scanning electron microscopy with a JSM6360LV (Japan), respectively. Semiquantitative analyses of phase contents in solid products were determined by the relative intensity ratio (RIR) method.

In conclusion, DASP can transform into APT in ammonium carbonate solution by hydrothermal transformation at 120C, but the tungsten conversion ratio is only 63.94% for 6 h. (3) In the (NH4)2SO4 system, ball-like, irregularly stacked APT particles can be obtained at 120C by hydrothermal transformation and the tungsten conversion ratio is greater than 90% for 6 h, while DASP can transform completely into quadrate APT by in situ transformation at 120C for 6 h.

- APT Manufacturer & Supplier, Chinatungsten Online: ammonium-paratungstate.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com