Concave Bismuth Tungstate Nanosheet Electrocatalyst Preparation

- Details

- Category: Tungsten Information

- Published on Sunday, 08 September 2019 10:36

Bismuth tungstate is the simplest orivis oxide with narrow band gap (about 2.7eV) and can absorb part of visible light. This material has been used for photocatalytic degradation of organic pollutants, photocatalytic organic reaction and photocatalytic decomposition of water.

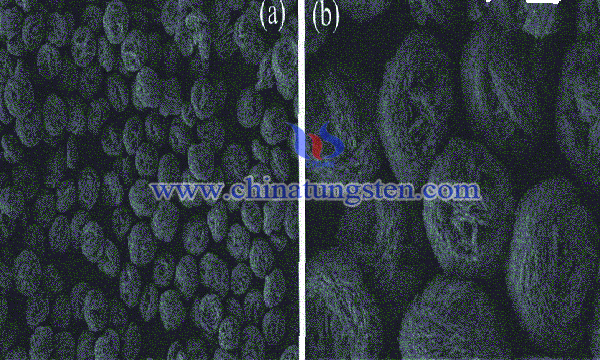

Some scholars have proposed a concave bismuth tungstate nanosheet electrocatalyst preparation. By controlling the synthesis conditions, using oxygen vacancies to improve the conductivity of materials, using oleamine selective adsorption to construct highly active concave nanosheets, and through the synergistic effect of defect engineering and crystal surface engineering to improve the catalytic activity of materials. Bi2WO6 nanosheets have been developed which can effectively catalyze the decomposition of water under near-neutral conditions. In near neutral water, the concave Bi2WO6 nanosheet exhibits higher electrocatalytic activity than the flat Bi2WO6 nanosheet, which is superior to the existing non-noble metal electrocatalysts for oxygen evolution. The preparation method of concave bismuth tungstate nanosheet electrocatalyst comprises the following steps:

(1) First, bismuth nitrate is dissolved in ethanol, stirred to dissolve completely, and recorded as solution A; sodium tungstate is dissolved in water, stirred to dissolve completely, and recorded as solution B; the molar ratio of bismuth nitrate to sodium tungstate is 4:1-1:4;

(2) Adding B solution to A solution and stirring;

(3) Adding 3-8mL oleamine to the mixed solution in step (2) and stirring continuously;

(4) The final solution in step (3) is added to the autoclave. The autoclave is sealed and placed in the drying chamber. The autoclave reacts at 220 ℃ for 4-10 h at constant temperature. After the reaction, the product is cooled to room temperature naturally. After the product is removed, the solid concave bismuth tungstate nanosheet Bi2WO6 is separated by centrifugation.

Amines are reducible, which can lead to the reduction of tungsten ions in Bi2WO6 nanosheets, resulting in corresponding oxygen vacancies. Oxygen vacancies can improve the electrical conductivity of materials. Oleimine selective adsorption constructs highly active concave nanosheets, which can be improved by the synergistic effect of defect engineering and crystal surface engineering. The concave bismuth tungstate nanosheet electrocatalyst has good catalytic activity in near neutral water, simple operation, green raw materials, low cost, short preparation cycle, good repeatability and can be prepared on a large scale.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com