Tungsten Alloy Counterweight in Elevators

- Details

- Category: Tungsten Information

- Published on Wednesday, 17 July 2019 17:04

Tungsten alloy counterweight is used to counterbalance an opposing mass in a linear or rotary motion system, allowing movement with lower driving forces. Tungsten alloy can be used as an ideal material for counterweight in elevators. Heavy metal tungsten alloys are 90% to 97% pure tungsten in a matrix of nickel and copper or nickel and iron. The addition of these alloying elements improves both the ductility and machinability of these alloys over non-alloyed tungsten.

What is Elevator?

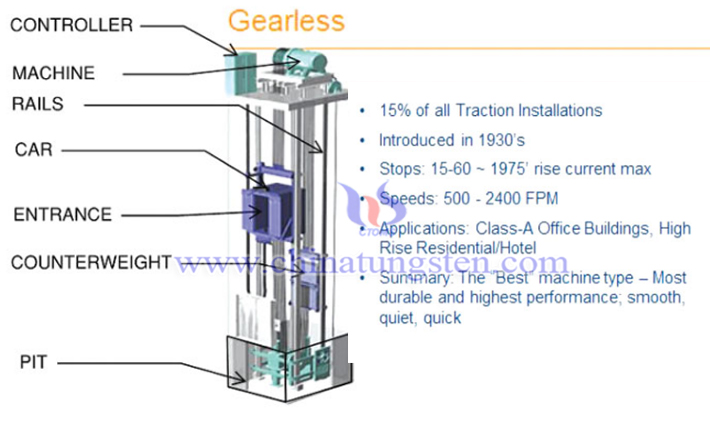

An elevator is a type of vertical transportation device that moves people or goods between floors of a building, vessel, or other structure. Elevators are typically powered by electric motors that drive traction cables and counterweight systems like a hoist, although some pump hydraulic fluid to raise a cylindrical piston like a jack.

How Tungsten Alloy Counterweight Works in Elevators?

In practice, elevators work in a slightly different way from simple hoists. The elevator car is balanced by a heavy counterweight that weighs roughly the same amount as the car when it's loaded half-full (in other words, the weight of the car itself plus 40–50 percent of the total weight it can carry). When the elevator goes up, the counterweight goes down—and vice-versa, which helps us in three ways:

- The counterweight makes it easier for the motor to raise and lower the car—just as sitting on a see-saw makes it much easier to lift someone's weight compared to lifting them in your arms. Thanks to the counterweight, the motor needs to use much less force to move the car either up or down. Assuming the car and its contents weigh more than the counterweight, all the motor has to lift is the difference in weight between the two and supply a bit of extra force to overcome friction in the pulleys and so on.

- Since less force is involved, there's less strain on the cables—which makes the elevator a little bit safer.

- The counterweight reduces the amount of energy the motor needs to use. This is intuitively obvious to anyone who's ever sat on a see-saw: assuming the see-saw is properly balanced, you can bob up and down any number of times without ever really getting tired—quite different from lifting someone in your arms, which tires you very quickly. This point also follows from the first one: if the motor is using less force to move the car the same distance, it's doing less work against the force of gravity.

The counterweight reduces the amount of braking the elevator needs to use. Imagine if there were no counterweight: a heavily loaded elevator car would be really hard to pull upwards but, on the return journey, would tend to race to the ground all by itself if there weren't some sort of sturdy brake to stop it. The counterweight makes it much easier to control the elevator car.

- Tungsten Alloy Manufacturer & Supplier, Chinatungsten Online: www.tungsten-alloy.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com