Epoxy Compounds by Tungsten Ionic Liquid Catalyst Preparation

- Details

- Category: Tungsten Information

- Published on Saturday, 27 April 2019 20:37

Epoxy compounds are important intermediates in organic synthesis and chemical raw materials. The ternary ring of epoxy compounds has special tension, so it is easy to synthesize many substances needed by people through selective ring opening or functional group conversion. Epoxy compounds have been widely used in many fields such as fine chemical industry, petrochemical industry, organic synthesis, pharmaceuticals, spices and so on.

In traditional olefin epoxidation reaction, the catalyst used is solid catalyst, and a large number of organic solvents, such as dichloromethane, are directly discharged into nature, polluting the environment. Therefore, the study of green and environmentally friendly olefin epoxidation reaction has always been an important topic in organic chemistry. Some scholars have tried to use tungsten ionic liquids as catalysts for olefin epoxidation.

Catalytic process:

1)Bromoalkane and N-methylimidazole were mixed evenly and refluxed for 1-10 h at 30-80 ℃. After cooling, the product was added to the mixture of acetonitrile and ethyl acetate, and refluxed for 12-72 h at 50-75 ℃. The filtrate was filtered by heat and crystallized after cooling to obtain [Cnmim] Br.

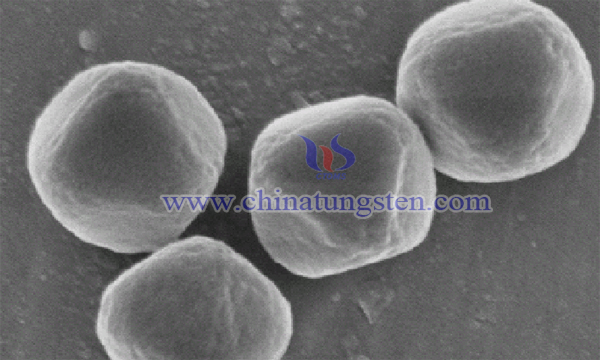

2)The [Cnmim] Br and sodium tungstate were added to acetone, stirred for 12-90 hours at room temperature, filtered, and vacuum distilled to remove acetone. The mixture of acetonitrile and ethyl acetate was recrystallized and vacuum dried for 12-72 hours to obtain tungsten ionic liquids.

3)Tungsten ionic liquids should be used to catalyze the epoxidation of olefins: the tungsten ionic liquids, oxidants and olefin substrates mentioned above should be taken, stirred, refluxed at 60-90 ℃ for 1-8 h, and the temperature should be reduced to 30-50 ℃. The organic phase should be extracted to obtain epoxy compounds.

Compared with the traditional olefin epoxidation reaction, tungsten ionic liquid catalyst has the advantages of simpler process, green and pollution-free reaction, recyclable catalyst, environmental protection and greatly reduced the cost of catalyst.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com