How to Reduce Agglomeration of Ultrafine Tungsten Carbide Powder

- Details

- Category: Tungsten Information

- Published on Monday, 08 April 2019 21:40

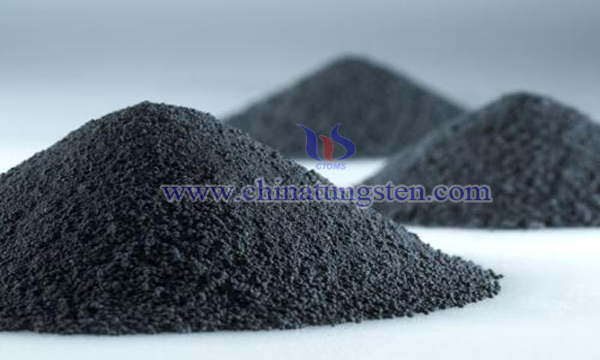

Ultrafine tungsten carbide powder commonly produced on the market is produced by carbon tube furnace or molybdenum wire furnace after mixing nanometer, ultrafine or fine tungsten powder with carbon black, then crushed by ball mill, and finally screened to obtain fine tungsten carbide powder products.

The tungsten carbide powder produced by this method has many particles which are not broken completely or aggregates. The particle size distribution is not uniform and concentrated enough. Some impurities are high and the stability of the product is poor. It is difficult to produce high-performance nanocrystalline, ultrafine-grained and fine-grained cemented carbides.

It is much more difficult to prepare ultrafine tungsten carbide powder than ordinary tungsten carbide powder because of its high activity, easy agglomeration and impurity mixing in sintering process, so the process requirements are very high. In order to reduce the phenomenon of incomplete fragmentation or agglomeration and make the particle size distribution of tungsten carbide powder more uniform and higher purity, some scholars have improved the carbonization process. The contents of the improvement are as follows:

The loading capacity is 3-7 kg and the pushing speed is 6-10 min/boat is carbonized through the hydrogen-molybdenum wire furnace. At the same time, the hydrogen flow rate in the hydrogen-molybdenum wire furnace is controlled to be 1.0-2.5 m3/h, and the temperature in the furnace is 1100-1350 ℃. Then the tungsten carbide block is broken into pieces through the air flow crushing system. Tungsten carbide powder can be dispersed.

The improved process shortens the production time, improves the labor efficiency and the output rate of primary products. The production process control is more stable. The prepared tungsten carbide powder is not broken completely or aggregates with very few particles, and the particle size distribution is very uniform and concentrated. Moreover, the impurity content of Fe, Co, Ni and Cr is lower, the single batch is larger, and the product stability is better. It can be used to produce high-performance sodium carbide safely. Cemented carbides with rice, ultrafine and fine grains.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com