Coarse-grained Tungsten Carbide Powder Preparation

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 22:55

At present, the main production mode of tungsten carbide powder is to mix tungsten powder with carbon powder for a long time in a high temperature environment with a protective atmosphere to obtain tungsten carbide powder with grain size of 2-5 micron. However, it is difficult to form a complete single grain of tungsten carbide with grain size of more than 10 micron, which has become a bottleneck restricting the production of coarse single crystal tungsten carbide mining cemented carbide tools.

Some researchers have proposed a method for preparing coarse-grained tungsten carbide powder. The preparation process is that tungsten atoms and carbon atoms are diffused and combined in high temperature liquid containing tungsten, carbon and iron to form a large number of tungsten carbide nuclei. During the slow cooling process, the tungsten carbide nuclei grow up gradually, forming coarse single-crystal tungsten carbide with grain size over 7 microns, and solidify with iron and dissolve with hydrochloric acid. Pure tungsten carbide powders with coarse single crystals are obtained by corrosion of iron from liquid. The specific operation process is as follows:

According to the weight, 5 portions of tungsten powder, 3 portions of iron oxide powder, 1 portion of carbon powder and 1 portion of aluminium powder are mixed evenly. They are put into a refractory crucible with two contacting carbon rod electrodes installed at the bottom and upper parts respectively. The upper carbon rod electrodes can move up and down. After electrification, the upper electrode slightly raises the ignition arc, preheat the powder and initiate exothermic reaction. Under the combined action of chemical heat and arc heating, the upper carbon rod electrodes can move up and down slightly. When the powder melts into a high temperature liquid, the current decreases slowly.

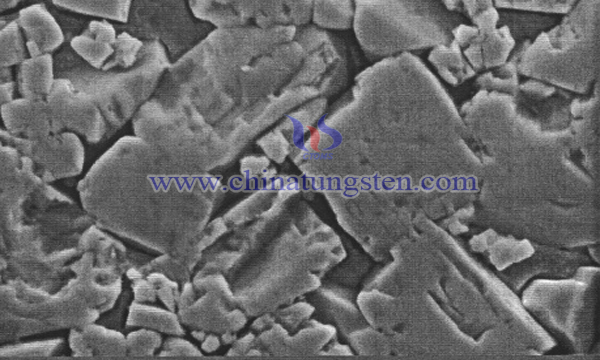

With the completion of the reaction and the gradual decrease of the current, the temperature decreases gradually. The tungsten carbide grains in the liquid begin to nucleate and grow. Most of them can grow to more than 10 micron, some can grow to about 70 micron, and the crystal shape is complete, the crystal defects are few. After all the liquids in the crucible are solidified and cooled to room temperature, they are taken out and solidified. Fixed block, put into hydrochloric acid solution, corrode the iron in the block, precipitate tungsten carbide powder to the bottom of the container, rinse it with clean water after filtration, sift it after drying, and sift out coarse single crystal tungsten carbide powder whose grain size exceeds 7 micron.

It is known that this method has the advantages of high production efficiency, low energy consumption, simple equipment and easy operation, and can produce coarse single crystal tungsten carbide powder with average grain size of more than 7 microns in batches.

- Tungsten Powder Manufacturer & Supplier, Chinatungsten Online: tungsten-powder.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com