New Nano Sized Tungsten Molybdenum Sulfide Hydrogenation Catalyst

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 22:48

Suspension bed hydrotreating technology is an advanced technology for preparing liquid fuel oil from heavy unconventional oil (residue, heavy oil/superheavy oil, shale oil, coal tar, sandstone oil, oil sand asphalt, etc.). Suspension bed hydrogenation process requires catalyst with high activity, high dispersibility, high stability and good economy. It is a challenging task to prepare catalyst for suspension bed hydrogenation process.

At present, the preparation methods of tungsten sulfide and molybdenum sulfide mainly include high temperature vulcanization method, precursor decomposition method, solvothermal method, electrochemical deposition method, template method and so on. However, the sulfide catalysts prepared by these methods are either water-soluble or oil-soluble. Because the composition of heavy oil is very complex and contains both polar and non-polar substances, the dispersion of tungsten sulfide with single surface compatibility is not ideal. Therefore, the synthesis of surface amphiphilic nano-sulfide catalysts by mild solution method is the key to improve their dispersion.

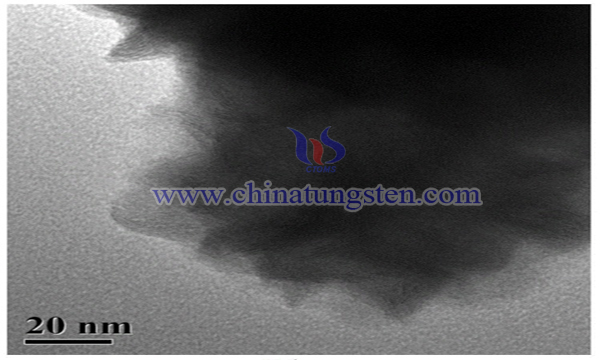

Surface amphiphilic nano sized tungsten molybdenum sulfide hydrogenation catalyst was prepared by solution chemistry with ionic liquids as additives, including the following steps: (1) adding tungsten and molybdenum sources to deionized water, mixing them evenly into a certain concentration of solution; (2) adding sulfur sources to the mixture, stirring them evenly and reacting at a certain temperature for a certain time; (3) adding reductant to the mixture, stirring them. Equilibrium; (4) Adding ionic liquids to the mixture, stirring evenly and configuring it into the initial reaction mixture; (5) Transferring the initial reaction mixture into the high-pressure synthesis kettle and crystallizing at a certain temperature for a certain time; (6) Cooling the reactant to room temperature after crystallization, using conventional methods of separating solid products, such as filtration, deionized water washing and drying, to obtain the surface parents nano tungsten molybdenum sulfide hydrogenation catalyst.

Because ionic liquids are used in the synthesis system, the prepared nano-molybdenum tungsten sulfide has good surface amphiphilicity, excellent dispersion and catalytic activity in polar and non-polar catalytic reaction systems. The product of nano-W-Mo sulfide hydrotreating catalyst exhibits very high catalytic activity in several reactions such as coal tar, heavy oil, super heavy oil, residue and shale oil, hydrodesulfurization, hydrodenitrification, hydro-dearomatics or hydro-deasphalting. It also has good application prospects in photoelectric conversion, photocatalytic water hydrogenation and other reactions.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com