Tungsten Disulfide Nanosheet-Graphene Heterostructure Composites

- Details

- Category: Tungsten Information

- Published on Monday, 01 April 2019 23:03

Graphene is the thinnest and strongest material known in nature. Graphene has high light transmittance, only about 2.3% light absorption, extremely high electron mobility (15,000 cm2/v * s) and very low resistivity. It is a new generation of transparent conductive materials.

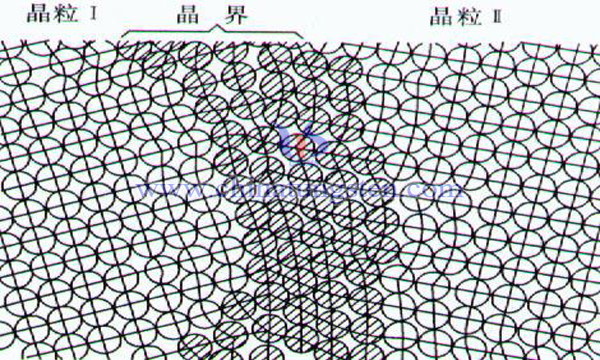

Tungsten disulfide is a kind of inorganic compound with layered structure similar to graphite. It can be peeled off by physical and chemical means to form nano-scale thin films with single atom thickness. Due to quantum effect and surface effect, tungsten disulfide nanosheets exhibit unique properties in electrical, optical and mechanical aspects. It is an important functional material in semiconductor electronic devices. Lithium ion batteries and catalytic hydrogen production have potential applications.

In recent years, a great deal of research has been done on the composites between nanomaterials at home and abroad. For example, heterostructured graphene-tungsten disulfide materials. Some scholars have used hydrothermal synthesis method to prepare tungsten disulfide nanosheet-graphene oxide heterostructure composites by combining tungsten disulfide nanosheet with graphene oxide, which improves its performance in lithium ion batteries, but the process is complex and difficult to control. Recently, some scholars have adopted liquid-phase ultrasound method, which has greatly improved the synthesis process.

The steps of preparing tungsten disulfide nanosheet-graphene heterostructure composites by liquid-phase ultrasound include:

(1)The ethanol dispersions of tungsten disulfide nanotablets with the concentration of 1 mg/ml and graphene ethanol dispersions with the concentration of 1 mg/ml were 80 ml and 10 ml respectively.

(2)Ultrasound power of 100 W was obtained by using a probe type ultrasonic equipment. The tungsten disulfide and graphene dispersions were measured at room temperature for 30 minutes.

(3)The two dispersions were mixed and used for 6 hours at 50 C and 300 W to make them uniform gray-black dispersions.

(4)Vacuum filtration was carried out by using microporous 0.1 um filter membrane, and filter cake was collected on the filter membrane.

(5) The filter cake was vacuum dried at 80 C for 2 hours, and 89.50 mg black solid was obtained as graphene-doped tungsten disulfide/graphene heterostructure with 11.11% graphene content.

As a result of the second ultrasonic dispersion, the multilayer tungsten disulfide nanosheets that did not meet the requirements of use were peeled off to a single layer or a few layers (1-6 layers), which improved the charge conductivity of heterostructures. After graphene modification, the two two two-dimensional layered structures can form heterostructures well, further improve the performance of tungsten disulfide nanosheets, and expand the application scope in semiconductor electronic devices, lithium ion batteries, catalytic hydrogen production, electromagnetic wave absorption and other fields.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com