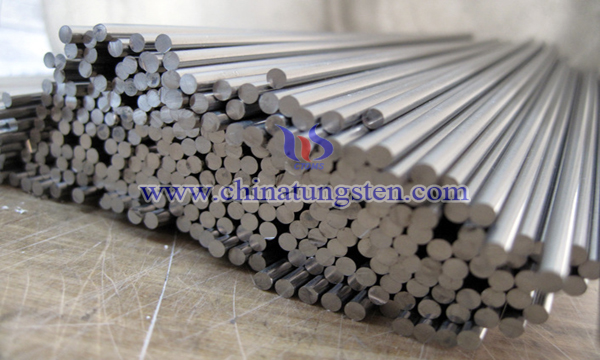

Large Size Thorium Tungsten Strip Manufacturing

- Details

- Category: Tungsten Information

- Published on Friday, 29 June 2018 21:10

The thorium tungsten electrode is the earliest rare earth tungsten electrode, and it is also the best tungsten electrode with the best welding performance so far. The existing methods for making tungsten strip are: tungsten powder, pressing, presintering and two vertical melt tungsten strips. However, this old technology is only suitable for the manufacture of small size bars. In the process of sintering and sintering of large size thorium tungsten bars, it is easy to cause the problem of the central sporadic large crystals of thorium and tungsten bars and the hidden danger of ThO2 high temperature burning. It is difficult to ensure the uniform distribution of the weight of ThO2 particles in the tungsten base.

Some scholars have proposed an improved method for manufacturing large size thorium tungsten strip, including the following steps:

(1) Tungsten powder doped with thorium powder with different granularity was pressed with the weight of 98% and 2% thorium oxide powder, with an average size of fuss 1.56 μm.

(2) After cold isostatic pressing, the billet strips were packed with 2.5kg powder with a cross section of Φ18.5 to 19.5mm. Pre sintering at 1350°C in hydrogen atmosphere.

(3) Adjustment of high temperature sintering process, 1.5min from room temperature to the first thermal insulation area, the first thermal insulation zone current of 2000A, thermal insulation time 2min, temperature range at 1600~1700°C; then 4min heating to second thermal insulation areas, the second insulation zone current is 3760A, thermal insulation time 8min, temperature range 2100~2500°C, then in 4min the temperature reaches third insulation zones, the third insulation areas are 4700A, the holding time is 30min, and the temperature range is 2700~2780°C. After threading, the thorium tungsten strip with a density of 17.6 ~18.0g/cm3, a diameter of 16.2 ~16.8mm, a weight of 2.4kg and a uniform distribution of ThO2 can be obtained.

The large size thorium tungsten strip was produced by adjusting the technological parameters, and the ThO2 particles in the large-size thorium tungsten strip were distributed evenly. Moreover, it needs only one vertical melting. As the thickness of thorium tungsten strip is large (2 ~ 5kg), compared with the existing 0.8 ~ 1.5kg billet, the process cost is reduced, and the production efficiency is increased.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com