Tungsten and Molybdenum Separation by Quaternary Ammonium Salt Extraction

- Details

- Category: Tungsten Information

- Published on Saturday, 02 June 2018 10:55

Separation of tungsten and molybdenum has been the focus of tungsten and molybdenum smelting technology research and development. Some researchers have proposed a method of extraction and separation of tungsten and molybdenum by extraction and separation of ammonium tungstate solution by N263- paraoctanol - kerosene system, which consists of 20% N263, 20% isooctanol and 60% kerosene, O/A=1:1.

N263, also known as chloromethyl three alkyl amine, is a quaternary amine salt extractant. In the tungsten smelting industry, it is often used to convert tungstate to ammonium tungstate. Since N263 has a quaternary amine type functional group with strong alkali anion characteristics, it has a strong affinity for sulfur and thiomolybdate ions, so there is a good separation effect of tungsten and molybdenum in the vulcanization system. It has obvious advantages in the preparation of high purity ammonium tungstate solution.

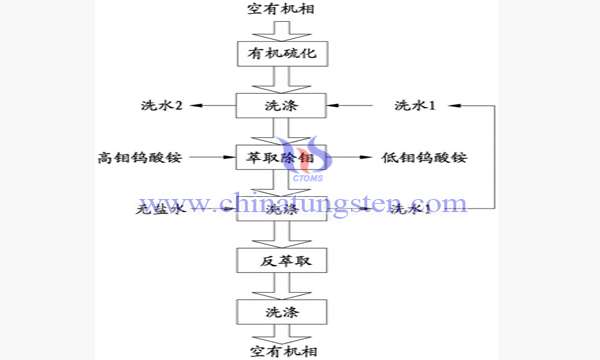

The organic phase can be obtained by mixing the empty organic phase with the vulcanizing agent and fully contacting it.

The ammonium molybdate solution was treated by adding high molybdenum ammonium tungstate into well sulfurized organic phase. After two levels of extraction and separation, the qualified ammonium molybdate solution was obtained.

The negative molybdenum organic phase after extraction can be oxidized by sodium hypochlorite and extracted from molybdenum to obtain sodium molybdate and empty organic phase. The solid and empty organic phases of molybdenum can be obtained with Fe3+ as oxidant, and the ammonium molybdate and empty organic phase can be obtained by oxidation of hydrogen peroxide and then stripping by ammonium chloride.

The organic phase vulcanization, the extraction of molybdenum removal and the reverse extraction each have one washing, and the extraction of molybdenum after removal of molybdenum is washed with no salt water as the raw liquid, and the residual liquid is washed as the organic phase after the vulcanization of the original liquid.

After using the above scheme, the vulcanization method before the extraction is to let the vulcanizing agent contact with the organic phase first. The effective component of the vulcanization is N235, which combines the S2- ion with the organic phase, and the ammonium tungstate solution does not need the vulcanizing agent to vulcanized the molybdenum, which solves the problem of the low efficiency and high cost of the traditional ammonium tungstate extraction and removing molybdenum.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com