How to Coat the Tungsten Substrate

- Details

- Category: Tungsten Information

- Published on Friday, 27 April 2018 16:27

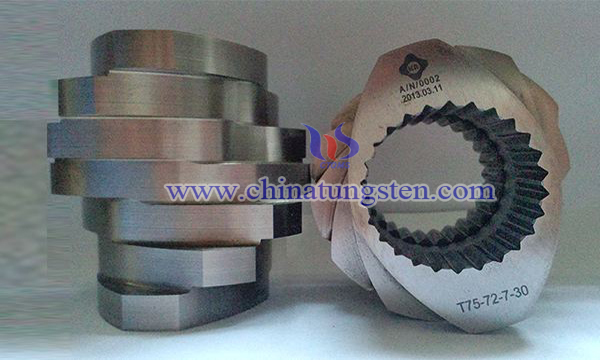

Tungsten coated materials can effectively improve the comprehensive performance of tungsten substrate materials, such as oxidation resistance, wear resistance, sweat stain resistance and colourful coloring. Generally, the coated tungsten materials are obtained by CVD or PVD method. The preparation process is more complex and the production cost is higher, and the density of the coating is poor, the thermal matching between the coating and the substrate is poor, and the structure of the coating is difficult to control. The main contents of the new technology are as follows:

The tungsten metal substrate is polished to a smooth surface, and then placed in anhydrous ethanol to dry and degrease. The tungsten substrate material is placed in the alumina crucible with molybdenum chemical permeation agent. The mass ratio of molybdenum powder, NH4Cl and Al2O3 is 40:5: 55, and the aluminous crucible is heated in a heating furnace. It is protected by nitrogen. The temperature rises to 1100°C at 10 °C /min and heat preservation for 5 hours, cooling to room temperature, boiling water in distilled water for 10min, anhydrous ethanol wiping and drying to get the semi finished metal tungsten surface as tungsten molybdenum solid solution layer; the semi-finished product is placed in the atmosphere furnace, through the 99.99% nitrogen of 300mL/min, to 5 centigrade /min liter. The temperature was increased to 1300°C for 20 hours and then cooled to room temperature. The 10min was cleaned by ultrasonic wave and the preform of tungsten nitride and tungsten nitride layer on the surface of tungsten was obtained. The preform was placed in the alumina crucible with silicified permeation agent, and the mass ratio of silicon powder, NaF and Al2O3 in the silicified infiltrating agent was 40:10: 50. The alumina crucible was heated in the heating furnace and protected by nitrogen gas. The heating rate was raised to 1400°C at 15°C/min and heat preservation for 15 hours. After the heat preservation, the temperature was cooled with the furnace to room temperature. Then it was removed and boiled in distilled water for 10min. The deionized water was washed, and the anhydrous ethanol was wiped and dried. The surface of tungsten matrix was obtained. W-Mo-N-Si is the finished product of the protection layer.

The new process uses molybdenum and nitridation + Silicification in situ reaction. Its advantages are simple in preparation and low in cost.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com