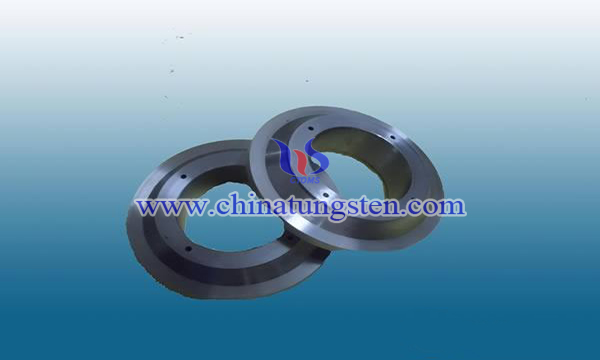

Steel Bonded Tungsten Carbide in Continuous Extrusion Die

- Details

- Category: Tungsten Information

- Published on Monday, 23 April 2018 22:01

As a newly-developed mould material, steel bonded tungsten carbide is a kind of tungsten carbide, on which there are 30%~50% hard particles. It is made by sintering and forging. Due to the small size of the die core, the linear expansion coefficient of H13 and steel bonded tungsten carbide is different. The design of the gap between the core rod and the core set is important as accidents that the core rod don’t fit the core set and the core rod is extruded may occur.

Processing technology of continuous extrusion die:

1, Determination of Processing Technology of The Core Rod

Plane: 50mmx27mmx6.7mm Square Stock.

Plain Grinding: Mill from 6.7mm down to 6.4mm.

Heat Treatment: Q-tempering.

Plain Grinding: Grind the thickness to 6mm to the tolerance size to ensure that the surface roughness is Ra0.8um.

Stroke: stroke the core contour line.

Wire-Electrode Cutting: With the thickness of 6mm up and down surface as the base, cutting mold core shape, cutting after cutting the amount of 0.02-0.03mm, to ensure that the uneven row degree of non-perpendicularity is not more than 0.015mm, the surface roughness is less than Ra1.6um.

Clamp: Grinding mold core 0.82mm, ensure the shape of 20.06mmx3.42mm, down the core on both sides of R1.71mm, the inverted core R 1.2mm, R 1.5mm, polishing R 1.0mm empty knife, to repair the transition part of the transition to make it smooth.

Assemble: assemble with the core set.

2, Determination of Grinding Quantity

After the wire-electrode cutting of core rod, due to the restriction of the processing conditions, it is necessary to do the grinding work. The grinding work can ensure the shape precision and position accuracy of the core rod. Generally, after wire-electrode cutting, the surface roughness is about Ra3.2um, of which the dimensional tolerances can be controlled within 0.01 mm. In order for the working part of the mold to reach Ra0.2um, boron carbide 120 is used for grinding, diamond WS is gradually lapping, and the abrasive volume is controlled at 0.015~0.02mm.

Through design improvement, the surface quality of the aluminum profile is improved, and the service life of the die is increased by more than ten times. In production trial, it is proved that steel bonded tungsten carbide can be widely used in extrusion die.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com