Effect of External Force on Sintering Shrinkage

- Details

- Category: Tungsten Information

- Published on Thursday, 08 March 2018 20:46

Many factors will affect the final densification effect, such as liquid solid wetting angle, liquid phase number, carbon content, heating rate and external force during sintering. For sintering of tungsten carbide, the most intense phase of the shrinkage process is the phase of liquid phase sintering. External force has a significant effect on the process of liquid-phase contraction, which is mainly reflected in the two aspects of promoting material migration and reducing porosity.

Promoting Material Migration

Research shows that the external force promotes the liquid phase flow and speeds up the densification process of the rearrangement of the particles. It increases the diffusion and dissolution rate of atoms on the surface of the particle. And plastic flow in particles in solid phase sintering stage caused by external force. Therefore, the external force is beneficial to the liquid phase sintering process.

Reducing Porosity

Low porosity is an important symbol of high quality tungsten carbide. It is one of the main pursuit of workers to reduce the porosity in the tungsten carbide as much as possible. The densification of tungsten carbide is directly related to the capillary force, the wettability of the liquid relative to the solid phase and the surface tension of the liquid.

When the liquid phase appears, the liquid phase moves toward the WC surface due to the capillary pressure. Due to the good wettability of the liquid relative to the WC phase, the liquid phase is well attached to the surface of the WC. With the surface tension, the WC that is encapsulated by liquid phase is driven to rearranged, and the intense contraction occurs. At this point, the gas that exists in the pressure block is discharged.

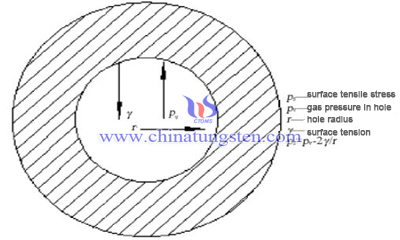

Some of the pores in the sintered body are closed by liquid phase. As the contraction increases, pressure is produced in closed pores. When the surface tension is equal to or less than the pressure in the pores, the closed pores are preserved in the alloy to form a microscopic pore. Outer pore is affected by liquid surface tension, while the gas in the cavity of the pore produces a reverse force. When the surface tension of the outer liquid is less than or equal to the gas pressure in the cavity of the cavity, the pore is stable.

The pressure outside the pores must be greater than the internal pressure to make sure that the γ phase and liquid phase infiltrate the pores along the capillary. That is to say, to reduce or eliminate the pores, it is necessary to apply a pressure to the liquid phase, so that the pressure outside the pore is greater than the pressure in the pore. When the residual pores are closed, the pressure will not have any affect longer.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com