Equation of Sintering Densification

- Details

- Category: Tungsten Information

- Published on Thursday, 08 March 2018 20:50

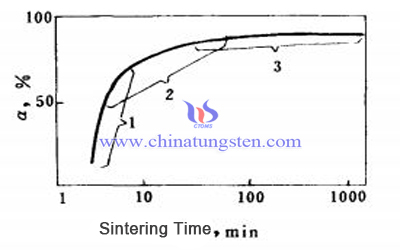

The sintering of tungsten carbide belongs to multicomponent liquid phase sintering. Its process can be roughly divided into 3 stages based on sintering mechanism: stage of liquid phase flow and particle rearrangement, stage of solid phase dissolution and reprecipitation and stage of solid phase sintering. Most of the densification is completed in the first two stages. Especially in the stage of particle rearrangement, the maximum amount of sintering shrinkage is completed.

Each stage of sintering appears one after another and overlap each other. As shown in the figure alongside above, 1- stage of liquid phase flow and particle rearrangement, 2- stage of solid phase dissolution and reprecipitation, 3- stage of solid phase sintering.

1, Densification Coefficient α

α=(ρs -ρg)/(ρt-ρg)*100%(1)

Where,

ρs--Sintered body density,

ρg--Green density,

ρt--Theoretical density of tungsten carbide.

2, Kinetic Equation of Each Stage

2.1, Stage of Particle Rearrangement

ΔL/L0=1/3*ΔV/V0=Kr-1t1+x (2)

Where,

ΔL/L0-- Line shrinkage,

ΔV/V0-- Cubical contraction,

r-- Radius of powder particle.

The formula shows that the densification rate caused by the rearrangement of particles is inversely proportional to the size of the particles. When x《1(1+x≈1), it is directly proportional to the time of sintering. In theory, with the shrinkage of the pores, the stress on the surface of the pores(σ=-2γL/r) increases, making the rate of liquid phase flow and pore contraction accelerate. However, the resistance of the liquid flow increases as the particles continue to close, and the contraction maintains a constant velocity. So, the sintering power at this stage is inversely proportional to the size of the particles, but the rate of liquid or particle rearrangement is independent of the absolute size of the particles.

2.2, Stage of Solid Phase Dissolution and Reprecipitation

ΔL/L0=1/3*ΔV/V0=Kr(-3/4)t(1/3) (2)

It is assumed that the particles are spherical, and the process is limited by the diffusion of atoms in the liquid phase.

2.3, Stage of Solid Phase Sintering

Compared with the first two stages, the rate of densification in this stage is very low, where exist only grain growth and volume diffusion. When there is an obturator, it is impossible to reach the density of 100%. The residual porosity is as follows:

a=(pr/2γL)3/2*a (1)

Where,

a-- Original porosity,

p-- Gas pressure in a closed hole,

r-- Radius of original pore,

γL-- Surface tension of liquid phase.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com