Bismuth Tungstate / Polyvinylidene Fluoride Composite

- Details

- Category: Tungsten Information

- Published on Wednesday, 07 March 2018 20:27

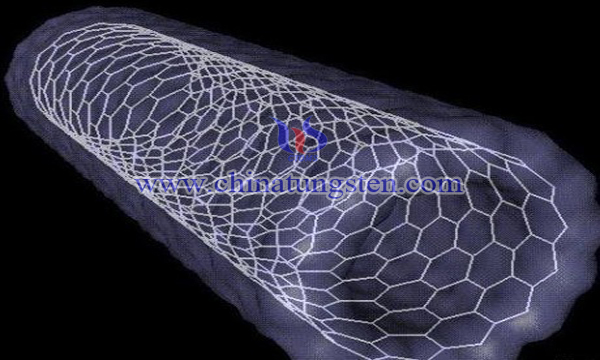

In recent years, bismuth tungstate (Bi2WO6) and tungstate semiconductor material, nano structure and due to their unique physical and chemical properties, it has good application prospects, such as used in magnetic devices, scintillation materials, corrosion inhibitor and catalyst, has become a research hotspot in recent years. Polyvinylidene fluoride (PVDF) has high dielectric constant and has good physical and chemical properties, can work for a long time in the environment of high intensity, easy to make a flexible film with special response materials in large area, so the collection of bismuth tungstate (Bi2WO6) and polyvinylidene fluoride (PVDF) / advantages of bismuth tungstate the prepared PVDF composite material has great application prospects in the field of dielectric materials.

The preparation method of bismuth tungstate / polyvinylidene fluoride composite material is as follows:

1.Pure nano bismuth tungstate powder was prepared by microwave hydrothermal method with Bi (NO3)3 / 5H2O and Na2WO4 / 2H2O as raw materials.

2.Preparation of 5% to 15% polyvinylidene fluoride N, N dimethylformamide solution, weighed polyvinylidene fluoride relative to the mass fraction of 5% to 10% nano bismuth tungstate powder, Adding polyvinylidene fluoride solution, magnetic stirring at a constant temperature of 30 ℃ to 40 ℃ for 8 hours to 24hrs, and then ultrasonicating for 1 hour to 5 hours to obtain a uniformly distributed suspension casting solution;

3.Remove the casting solution was suspended in a glass vessel by spin coating method at a constant temperature of 40 ℃ ~ 100 ℃ hot stage thermal curing film obtained bismuth tungstate / polyvinylidene fluoride composite film;

4.The multilayer bismuth tungstate / polyvinylidene fluoride composite film is folded and placed in a hot-pressing mold, and then the mold is placed on a powder tabletting machine. The initial molding temperature is 185 ℃ to 205 ℃, the molding pressure is 5 MPa to 30 MPa, the constant temperature 1 ~ 30min, molding, and then quickly remove the mold pressure, the mold temperature was adjusted to 130 ℃ ~ 160 ℃ temperature, crystallization temperature 8h ~ 60h, the crystal was completely bismuth tungstate / PVDF composite material.

The nanometer bismuth tungstate powder has the crystal morphology of lamellar porous loose spheroidal coil with the spherical particle size of 2 um to 4 um and the large gap spacing of the film, and the composite material has good bonding strength , as well as physical and mechanical properties. And in the visible and ultraviolet regions with strong absorption than PVDF increased nearly 100%, proved that the flexible film has a good combination of nano bismuth tungstate light response characteristics, the future in the ferroelectric flexible material sensor, and has a broad market prospect and the photocatalytic wastewater treatment film applications.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com