Tungsten Oxide Electrode Electrochemical Properties

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:18

To study the electrochemical performance of the tungsten oxide electrode material, the charge-discharge curve of the tungsten oxide electrode material at a constant current density of 100 mA was tested at room temperature. The test voltage range was 0.005-3.0 V. In the first cycle of charge and discharge process, the tungsten oxide electrode discharge capacity of 1811mA, charge capacity of 1168 mA, Coulomb efficiency of 64.5%.

The first charge and discharge coulombic efficiency is relatively low mainly with the formation of solid electrolyte interface membrane and the decomposition of the electrolyte, which is consistent with the results of most voltammetry curves. In Cycle 10, the discharge capacity was 1146 mA, the charge capacity was 1115 mA, and the coulombic efficiency was as high as 97.3%. In the 20th lap after the 30th lap cycle, Coulomb efficiency remained above 95%. This value is much higher than the earlier reported tungsten oxide anode material. It shows that the tungsten oxide electrode material not only has higher coulombic efficiency, but also maintains good cycle stability. Moreover, the reversible capacity of the tungsten oxide cathode material is higher than the theoretical capacity of the tungsten oxide cathode material, indicating that the tungsten oxide electrode has excellent lithium storage performance.

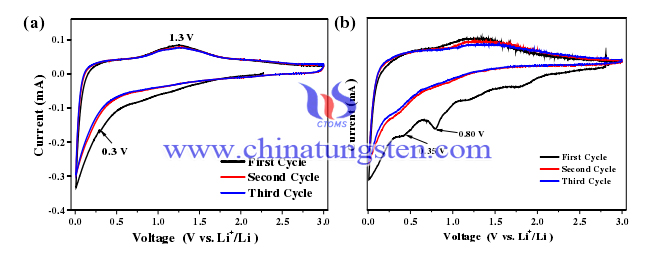

t can be observed in the voltammograms of the first three turns of tungsten oxide that a very weak peak is observed at a voltage of 0.3 V in the first lap cycle due to the formation of the SEI film. In the subsequent cycles, the volt-ampere characteristic curves are almost coincident, indicating that tungsten oxide materials have good structural stability during irreversible electrochemical processes. To compare the electrochemical performance of tungsten oxide electrode materials, the voltammetry curves of tungsten oxide materials were tested under the same conditions. Note that the tungsten oxide electrode material has two oxidation peaks at 0.35 V and 0.80 V. This is the formation of tungsten oxide electrodes during lithium insertion and DE lithiation. For tungsten oxide electrode materials, the peak intensity at 0.3V is weak.

This shows that after the carbon material is coated, the formation of the SEI film can be effectively prevented, thereby obtaining higher coulombic efficiency.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com