Polypyrrole Coated Defect Tungsten Oxide

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 09:26

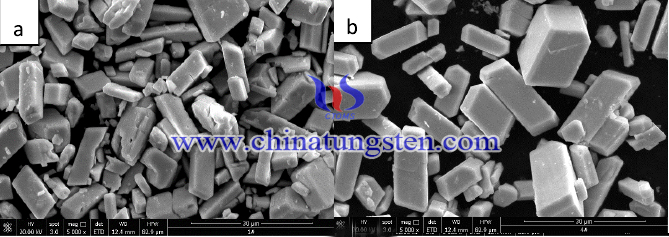

Polypyrrole-coated defect tungsten oxide composites were prepared by chemical polymerization, and then the defect tungsten oxide composite, nitrogen-carbon doped tungsten oxide, was obtained by calcination at high temperature. The synthesis of these two parts is as follows:

Polypyrrole coated defect tungsten oxide material carbonized preparation process is as follows: the polypyrrole coated sample placed in a vacuum tube furnace for carbonation. First, the tube was purged with nitrogen for 30 minutes to evacuate the air in the tube. Subsequently, nitrogen gas was continuously heated to 550 ° C., and the mixture was naturally cooled to room temperature after being kept for 3 hours to obtain the tungsten oxide composite. Thermogravimetric analysis is based on the material in a certain atmosphere of the decomposition temperature is different through the temperature control, testing the quality of the sample with the temperature changes in the relationship between the composite material to get the content of each component.

Defective tungsten oxide and pyrrole as the main raw materials, through the chemical polymerization and high temperature carbonization method successfully prepared a defect-coated tungsten oxide composite material. A series of characterization and analysis of tungsten oxide composites were carried out. The electrochemical properties of the composites were also studied as cathode materials for lithium ion batteries. The test results show that the specific capacity of the tungsten oxide composite reaches 1004.3 mA at a current density of 100 mA. And at current density of 200mA, after 150 cycles of test cycle, the discharge capacity is still up to 520mA, indicating that tungsten oxide has a very high reversible capacity and good cycle stability.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com