Tungsten Oxide Composite Electrode

- Details

- Category: Tungsten Information

- Published on Friday, 02 March 2018 08:57

The discharge rate performance of the two electrode materials of tungsten oxide composite electrode and tungsten oxide electrode can be obtained by subjecting the material to multiple charge-discharge cycles with different current densities. Tungsten oxide composite electrodes have reversible capacities of 1004, 795, 578, 400 and 243 mA at current densities of 100, 200, 500, 1000 and 2000 mA, respectively.

In contrast, the tungsten oxide electrode material exhibits a very pronounced capacity decay phenomenon at increasing current densities, with a discharge capacity of only 93 mA, especially at a current density of 1000 mA. For tungsten oxide composite electrode composite, the current density of 1000mA, the discharge capacity of up to 400mA. When the current density back to 100mA, the tungsten oxide composite electrode discharge capacity can still be back to 870mA. In summary, the defects of tungsten oxide coated with carbon material can effectively improve the reversible capacity and cycle stability of the defective tungsten oxide material.

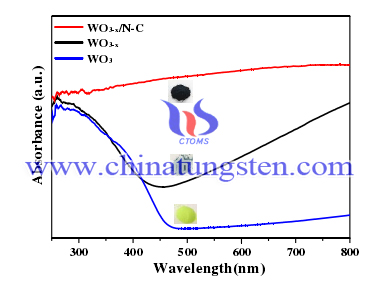

The main reasons for the great difference in performance between the two electrodes include the following: First, the XPS and UV-Vis absorption spectra of the two kinds of electrodes show that the tungsten oxide composite electrode contains a large number of defects in structure. Studies have shown that the existence of defects can improve the electronic conductivity, but also accelerate the lithium-ion battery migration. Secondly, the carbon coating on the surface of the tungsten oxide composite electrode composite can effectively block the electrolyte and the active material, thereby avoiding the repeated production of the SEI film. Finally, tungsten oxide composite electrode composite due to its high specific surface area. The contact area with the electrolyte is large and has more reaction sites, so the activity of the tungsten oxide composite electrode is higher.

- Tungsten Oxide Manufacturer & Supplier, Chinatungsten Online: www.tungsten-oxide.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com