Effect of Grain Size on Sintering Densification

- Details

- Category: Tungsten Information

- Published on Sunday, 25 February 2018 18:14

The sintering of tungsten carbide is a kind of liquid phase sintering. The wettability of liquid phase, the solubility of solid phase in the liquid phase and the quantity of liquid phase are three basic conditions of liquid phase sintering, which are also the basic factors.

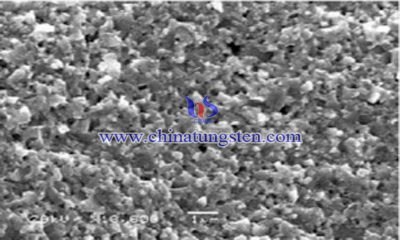

In addition, the density of the blank, the grain size, the uniformity of the mixing of the powder, the sintering temperature, the time and the atmosphere are also the basic factors for the sintering densification. Among these factors, the grain size plays an important role. As the particle is smaller, the fluid flow and the flow of particles caused by the capillary action are smooth, and the dissolution - precipitation speed is faster, making a better the densification effect.

Effect of Grain Size on Capillary Action

The smaller the carbide particles are, the shorter the center distance of the particles is, and the smaller the radius of the single pore in the body are. According to the formula of capillary action:

h=2γcosθ/(ρgr)

γ= Surface tension,

θ= Contact angle,

ρ= Liquid density,

g= Acceleration of gravity,

r= Tube radius.

The capillary pressure of a liquid is inversely proportional to the radius of the hole. Under the action of larger capillary force, the flow of particles will be smoother. At the same time, the center distance of the two carbide particles is shortened with the decrease of the particles. When fine particles are sintered, they are easy to close each other, which is beneficial to the improvement of the speed of densification.

Effect of Grain Size on Dissolution Precipitation

As the particle size decreases and the specific surface increase, the velocity of solid diffusion and the rearrangement and dissolution rate of the liquid phase are greater after the appearance of the liquid phase. According to the formula of concentration difference, ΔN=2γslδ3 /(kTrN), as the degree of surface saturation (degree of saturation) is larger, more particles will dissolve, and small particles are dissolved before larger particles.

Therefore, the mixture of grind mixture and raw grain is quite different from the shrinkage characteristics of general mixture. It significantly reduces the temperature of the contraction began to appear, and also improves the densification speed before the temperature range of liquid phase.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com