Comparison of Various Sintering Mechanisms

- Details

- Category: Tungsten Information

- Published on Tuesday, 20 February 2018 18:50

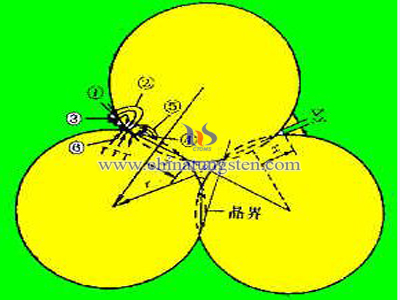

The sintering mechanism of tungsten carbide mainly includes viscous flow, evaporation in condensation, volume diffusion, surface diffusion, grain boundary diffusion, plastic flow and so on. Various sintering mechanisms have some similarities and differences. The actual sintering process is much more complex than the model study, and various mechanisms may occur simultaneously or alternately during a certain sintering process.

Common Points of Various Sintering Mechanisms

Although various sintering mechanisms are different in describing the sintering process, the dynamic equations are all satisfied with a general formula.

xm/an=F(T)t

x-- Radius of the sintered neck,

a-- Particle radius,

m、n—Constant, different for different mechanisms,

F(T)-- Temperature related constants,

t-- Sintering time.

Scope of Application

1, Under the effect of lower temperature and stress, the viscous flow and the plastic flow mechanism play a role. The viscous flow is more suitable for non-metallic powder, WC powder of tungsten carbide, for example. Plastic deformation is more suitable for metal powder, which corresponds to the Co powder of tungsten carbide.

2, At high temperature, the mechanism of grain boundary diffusion and volume diffusion plays an important role. Grain boundary diffusion is born with volume diffusion and does not work alone. However, the activation energy of grain boundary diffusion is only half of the volume diffusion, and its diffusion coefficient is 1000 times larger. So the diffusion of grain boundary is easier to carry on.

3, The surface diffusion plays a very important role in the sintering of the smaller grain size. Surface diffusion occurs at the initial stage of sintering, which results in pore shrinkage and volume change. It does not change volume at the later stage of sintering, and only leads to the change of pore surface condition and shape.

4, Vapor pressure of tungsten carbide powder is low. The mechanism of evaporation-condensation is not the main mechanism, but it will change the shape of the pore.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com