Classification of Sintering

- Details

- Category: Tungsten Information

- Published on Friday, 09 February 2018 18:43

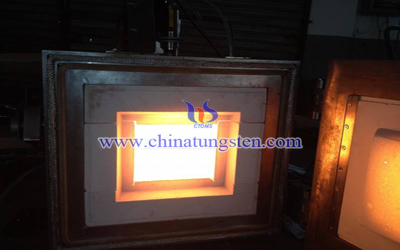

Sintering is the most important process in the production of tungsten carbide. Different sintering processes have different effects on the properties of the sintered products. Sintering can be classified according to the number of components in sintered products, and it can also be classified according to the phase state of components in sintering process, of course, it can also be divided according to sintering process.

Classification According to the Sinter Component

It can be divided into unit and multicomponent sintering. A single remote system consisting of pure metals, compounds, or solid solutions. A multiphase system consisting of metal, nonmetallic, and metallic compounds. Tungsten carbide material belongs to the multicomponent powder, so it belongs to the multi system sintering.

Classification According to the State of Sintering Phase

According to the phase state of the component, it can be divided into solid phase sintering and liquid phase sintering. The liquid phase sintering process of tungsten and molybdenum does not appear, belong to solid phase sintering. In the production of tungsten carbide products, liquid phase will appear. So, it belongs to liquid phase sintering.

For multicomponent solid phase sintering, it can be divided:

1, Unlimited Solid-Solution System

In the state diagram of the alloy, there are systems of infinite solid solution areas, such as W-Mo, Cu-Ni, Fe-Ni and so on.

2, Limited Solid Solution System

In the state diagram of the alloy, the system with finite solid solution area is common, such as W-Ni, Fe-C and so on.

3, Completely Immiscible System

A system that neither dissolves nor forms a compound or other intermediate phase between the components, such as Ag-W, Cu-W and other "false alloys".

The sintering of tungsten carbide belongs to the multicomponent liquid phase sintering for multicomponent liquid phase sintering, the sintering process to exceed the system of low melting component melting temperature. Due to the nature of the low melting component with refractory solid dissolve each other or the formation of alloy, liquid phase may disappear or always exist in the whole process.

1, Stable liquid phase sintering

Tungsten carbide (WC-Co, TiC-Ni) and tungsten alloy (W-Cu, W-Cu-Ni).

2, Transient liquid phase sintering

Such as: Cu-Sn, Cu-Pb, Fe-Ni-Al and so on.

Classification According to the Sintering Process

According to the technological characteristics, it can be divided into hydrogen sintering, vacuum sintering, activated sintering, hot isostatic pressing sintering, microwave sintering and so on. Many sintering methods can be used for sintering of tungsten carbide.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com