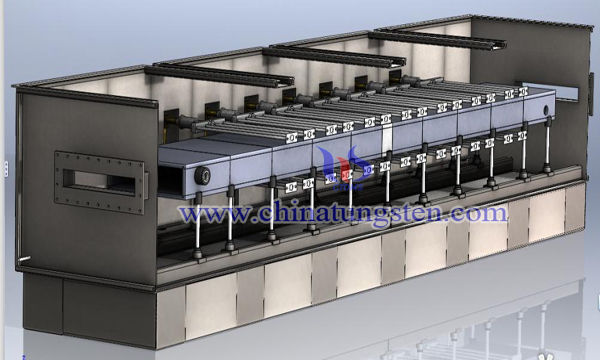

A New Kind of Tungsten Carbide Continuous Carbonization Furnace

- Details

- Category: Tungsten Information

- Published on Monday, 05 February 2018 21:14

High-quality ultra-coarse tungsten carbide powder, often made into ultra-coarse tungsten carbide that have good strength and toughness etc., are widely used in many fields such as oil drilling, mining tools, stamping dies and hard surface materials etc.

The preparation method of the traditional ultra-coarse tungsten carbide powder in China is as follows: the raw materials of fine tungsten powder and the carbon black are dry-mixed with a ball mill, and after fully mixed get pressure-molded, and then are put into a carbonization furnace for high-temperature carbonization and sieving of ball milling. The production process of this technique is relatively complicated, time-consuming, easy to mix impurities, and the mixing of tungsten and carbon being prone to be uneven in the first ball milling with carbon, resulting in carbonation process segregation, impermeable carbon black and low carbon content phenomenon. If followed by ball milling with carbon, it will reduce the Fischer-fischeri particle size of ultra-coarse tungsten carbide that makes it hard to meet the standard of ultra-coarse tungsten carbide powder.

In view of the disadvantages of the traditional ultra-coarse tungsten carbide powder preparation methods, such as complicated procedures, low efficiency, difficult removal of tungsten carbide powder and the production cannot meet the requirements of higher and higher production requirement. Therefore, it becomes more and more important to invent a carbonization furnace that has simple manufacturing process, high efficiency, easy to remove tungsten carbide powder and high quality output.

In order to solve the above technical problems, some manufacturers have designed a fully automatic, vertical, continuous and high-efficiency carbonization furnace of ultra-coarse tungsten carbide, including a valve I, a carbonization furnace, a temperature sensor, a valve II, a tungsten powder tube, a tungsten powder tank , tungsten powder spray gun, heating plate, toner gun, toner tank, toner tube, valve Ⅲ, control system, pressure sensorⅠ, push plate, cylinder, pressure sensorⅡ, pressure sensor board and discharge port and other components.

The working principle of carbonization furnace: Start the control system then the heating plate start to work. The temperature sensor senses the temperature inside the carbonization furnace and passes the data to the control system. When the temperature reaches the set requirements, the control system sends signals to the valveⅠ, valveⅡ , Valve Ⅲ and cylinder to close the valveⅠand open the valve Ⅱand valve Ⅲ and contract the cylinder. Then, the tungsten powder in the tungsten powder tank will be sprayed into the carbonization furnace through the tungsten nozzle; the carbon powder in the carbon powder tank will be sprayed into the carbonization furnace through the carbon nozzle. The carbon and tungsten powder get reacted and constantly fall on the pressure sensor board, which send the data to the control system. In the same time, pressure sensorⅠcontinually monitoring the pressure inside the carbonization furnace, the control system compares the data from the pressure sensorⅠwith the pressure from sensor board, when the data reaches the set requirements the control system opens the valveⅠto control the cylinder elongation. The tungsten carbide powder is discharged from the discharge port by the pushing board. When the pressure sensorⅡtouches wall of carbonized furnace, the pressure of pressure sensor Ⅱ increasing, and passes the data to the control system which controls the air cylinder contract and get homing.

Compared with the conventional tungsten carbide, the new carbonization furnace overcomes the problems of the traditional ultra-coarse tungsten carbide powder preparation method that are complicated procedure, low efficiency, hard to remove the tungsten carbide powder and the output ultra-coarse tungsten carbide powder failing to meet the higher and higher production requirements, and has the advantages: simpler process, high efficiency, easy to remove tungsten carbide powder and better product.

- Tungsten Manufacturer & Supplier, Chinatungsten Online: www.chinatungsten.com

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com