Dynamic Magnetic Compaction: Technology and Equipment

- Details

- Category: Tungsten Information

- Published on Friday, 22 December 2017 21:44

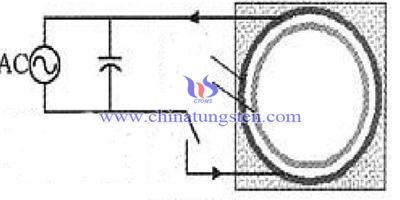

The press compact made of dynamic magnetic compaction has many advantages, such as high forming density, superior mechanical properties, short forming time and wide application. Similar to the common molding process, the equipment is composed of four parts: pulse power supply, electromagnetic field coil winding, material delivery system and programmable logic controller system.

Technology of Dynamic Magnetic Compaction

Similar to the common cemented carbide molding process, technology of dynamic magnetic compaction includes outer ring jacket (similar to compacting tool set), powder filling, blanking and subsequent sintering process.

Of course, if the product has high precision and surface requirements, it also needs to be machined. In most practical applications, powder filling and compaction are carried out at room temperature, and the filling of powder can also be carried out under special conditions, such as inert gas or other gas protection. With appropriate equipment, the blank can also be formed at high temperature.

Equipment of Dynamic Magnetic Compaction

At present, the forming equipment system of dynamic magnetic is mainly composed of four parts: pulse power supply, electromagnetic field coil winding, material delivery system and programmable logic controller system. The system can achieve a high production rate of 10 parts per minute, and various functional components such as powder filling and conveying device can be easily attached to the system when needed.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com