Characteristics of Dynamic Magnetic Compaction

- Details

- Category: Tungsten Information

- Published on Friday, 22 December 2017 21:48

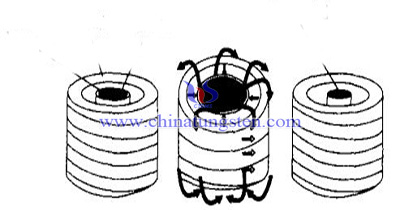

Dynamic magnetic compaction has many advantages, such as high forming density, superior mechanical properties, short forming time and wide application. However, because only radial pressure can be used, it can only be applied to cylindrical symmetric tungsten carbide products. And it still has many problems, for example high energy consumption. Specific characteristics of dynamic magnetic compaction are as follows.

Advantages of Dynamic Magnetic Compaction

1, Fast Speed

The pressing time is less than 1ms, and the forming efficiency is very high, which is very suitable for some metastable powders. For example, when suppress amorphous or nanocrystalline tungsten carbide powder, the mechanical properties and dimensional accuracy are much higher than those of the conventional pressing parts.

2, No Dies Required

In addition to dies, lubricants and adhesives are not required too. And the process can be carried out in any temperature and atmosphere.

3, Products with High Density and Superior Mechanical Properties.

The green density is above 95%, which is close to the theoretical density. Because of the rapid forming speed, the microstructure of the material can be kept constant as far as possible, thus the performance of products is better than that of other formation methods. The high density of the blank reduces the sintering shrinkage rate, which is beneficial to control the dimensional precision of the products.

4, Wide Application

It can form parts with high ratio of length to diameter, and it can form a product with large length in theory.

Disadvantages of Dynamic Magnetic Compaction

1, The dynamic magnetic compaction is radial compression, and the powder in the central part may lack of suppression because of the conductor skin effect. At present, it is only suitable for forming cylindrical symmetry products.

2, Induction current produced by the induction magnetic field has a sintering effect on the powder.

3, It is energy-guzzling.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com