Extrusion Process Control of Tungsten Carbide

- Details

- Category: Tungsten Information

- Published on Monday, 06 November 2017 22:47

The extrusion process of tungsten carbide is affected by various parameters, among which extrusion temperature and extrusion speed are the two key factors.

1, Extrusion Temperature

It is directly related to the process conditions and process of plasticizing, fluidity and stress level of the feeding material. The choice of temperature is related to the characteristics of feedstock.

Excessive extrusion temperature will cause a sharp drop in extrusion pressure, which will lead to softening deformation of the blank, and the density and strength of the blank will be too low. The low extrusion temperature will lead to the increase of extrusion pressure, the roughness of the blank becomes worse, and the delamination or crack is easy to occur. Extrusion temperature is too high, easy to produce non-compaction, uneven density distribution and other phenomena.

2, Extrusion Speed

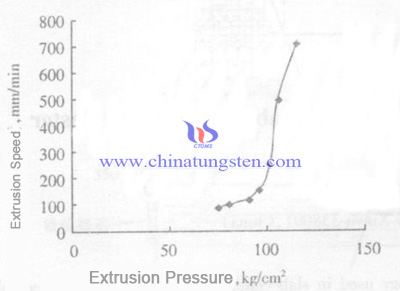

Relationship between extrusion speed and extrusion pressure is shown above. The extrusion pressure is mainly used to overcome the deformation flow of the binder, the internal friction of the powder, and the friction between the extrusion material and the extrusion nozzle.

Therefore, when the extrusion pressure is large enough to overcome the above resistance, the extrusion pressure is mainly used to increase the extrusion speed after the extrusion. The extrusion speed mainly affects the flow behavior of the feed. Generally, the feed flow rate increases with the increase of extrusion speed.

In a certain range, the extrusion speed has little effect on the quality of the blank. Therefore, the selection of extrusion speed is mainly based on the production efficiency and ease of operation. Too low extrusion speed will produce " bamboo joint " shape marks. But too high extrusion speed often produces non-compaction, uneven density distribution and other phenomena, resulting in bending deformation in the subsequent sintering process.

- Tungsten Carbide Manufacturer & Supplier, Chinatungsten Online: tungsten-carbide.com.cn

- Tungsten News & Prices of China Tungsten Industry Association: www.ctia.com.cn

- Molybdenum News & Price: news.molybdenum.com.cn

- Tel.: 86 592 5129696; Fax: 86 592 5129797; Email: sales@chinatungsten.com

sales@chinatungsten.com

sales@chinatungsten.com