Ammonium Metatungstate Producing Method

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:44

Ammonium metatungstate producing method includes neutralization method, tungstic acid method, thermal decomposition method, solvent extraction method and ion exchange method.

Neutralization method uses secondary ammonium metatungstate and nitrate as the raw material to produce metatungstate.

Tungstic acid method using ammonia tungstate tungstic acid dissolved, add a boil deionized water in the stirring, heating by ammonia, Ph=8, in the boiling solution by adding acetic acid.

Thermal decomposition method combines ammonium paratungstate and a small amount of citric acid catalyst after mixing into the far infrared, rotary furnace, controlled thermal decomposition temperature 200 ~ 280 ℃, decomposition of about 1 h.

Solvent extraction using ammonium tungstate solution and organic extractant phosphoric acid: two (2- ethylhexyl) ester (D2EHPA) or phosphoric acid butyl ester three (TBP) and kerosene solvent to form organic phase, extract ammonium ion from ammonium tungstate solution.

Ion exchange method uses ammonium paratungstate as raw material, heating ammonium paratungstate from 1 to 8 h at 130 ~ 140 ℃, the resultant tune into a paste, to 80 ~ 100 ℃ boiling for 2 ~ 6 h, generates ammonium metatungstate solution. And then obtain the product through concentrating crystallization, filtration and drying.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Paratungstate Producing Method

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:43

Ammonium paratungstate producing method includes evaporation crystal method, neutralization crystal method and lyophilization crystal method.

Evaporation crystal method is the most widely applied in industry. Reduction evaporation is common used in the producing process. Vacuum pressure is maintained around 40kpa, evaporation temperature is between 353-363k, producing the strip of crystallization and the component of which is 5(NH4)2O•12WO3•5H2O3.

Neutralization crystal method neutralizes hydrochloric acid with concentration of 10%-20% and ammonium tungstate solution to ph value 7. If neutralizing acid under temperature 363-368k, after an hour ammonium paratungstate is produced by crystallization. If adding acid under room temperature, the solution needs to be stewing for 8-12 hours, sometimes even 24 hours, the finished ammonium paratungstate is of shape like needle and the component of which is 5(NH4)2O•12WO3•11H2O.

Lyophilization crystal method freezes ammonium tungstate solution first and heat it under vacuum low pressure environment which can obtain polyporous and drying ammonium paratungstate.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate New Producing Method

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:40

Using a coupling process of neutralization–nanofiltration–crystallization, pure ammonium metatungstate (AMT) was prepared. The effects of chemical neutralization of ammonium paratungstate (APT) by nitric acid, operating pressure, AMT concentration, the volume of washing water on the coupling process were systematically discussed.

It was found that the better conditions of AMT preparation were as follows: the neutralization temperature was 80–95 °C, pH value was 2.0–3.5; the operating pressure of HDS-12-2, nanofiltration was 1.5–2.0 MPa, the density of AMT crystallization solution was 2.39 kg/L, and then cooling. APT conversion efficiency (δ) to AMT was more than 97.62%. The removal ratio of nitrate ion (NO3−) was more than 99% while AMT rejection (RAMT) was 99.9%. Besides, small-grained, even-proportioned, white-colored and high-purified AMT crystal was be obtained and analyzed. This method has several advantages such as simple technological process, short production cycle, lower environmental pollution and high quality.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Ammonium Metatungstate Structure Study

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 16:39

Several techniques have been used to study the structure of the Keggin-type polyoxometalate salt ammonium metatungstate (AMT)—(NH4)6[H2W12O40]*nH2O, a potential fuel cell catalyst. The dehydrated salt is comprised of a mixture of crystallites of different unit cells in a centered eutactic cubic configuration. Varied orientations of the Keggin ions in the cubic arrangement create the differences, and orientational variation within each unit cell size represents an energy well. Progressive hydration of each crystallite leads to expansion of the lattice, with the degree of expansion depending on the locations of the water added in relation to the Keggin ion, which is influenced by cation location and hydrogen bonding. The structural hypothesis is supported by electron diffraction of single and multicrystal samples, by powder density measurements, X-ray powder diffraction studies, synchrotron powder X-ray diffraction, anda priori structural modeling studies. Based on the structure, projected active site densities are compared with nanostructured platinum catalysts for fuel cell application.

The structure of ammonium metatungstate powders are highly dependent on hydration and POM molecule rotation, with cation and hydrogen bonding forces directing a mixture of structures that have been studied with bulk and single-crystal methods. The illustration shows Monte Carlo simulated anion structural disorder for the fully dehydrated form of the title compound.

Tungsten Manufacturer & Supplier: Chinatungsten Online - http://www.chinatungsten.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Installation Method of Tungsten Contacts in Automotive Relay

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:59

Installation method of tungsten contacts in automotive relay described below:

To maximize the performance of the automotive relay, the mounting direction should be consistent with the impact resistance direction of the automotive relay. That is, in order to effectively improve the anti-shock and impact resistance performance of the normally closed tungsten contacts in the non-energized state, impact direction should be perpendicular to the direction of movement of the armature and the tungsten contacts.

When it is installed, in order to improve contact reliability, the axial of tungsten contacts of automotive relay should parallel to the ground, to avoid spatter tungsten contacts, tungsten carbide falling on tungsten contacts surfaces.

If installing multiple sets of automotive relay, you should avoid large load tungsten contacts on the top of small load tungsten contacts.

If install large volume of relays, in order to prevent the mounting feet will damage in the condition of shock and vibration, you can choose housing mounting method.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Working Principle of Tungsten Contacts in Automotive Relay

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:44

Working principle of tungsten contacts in automotive relay:

Automotive relay can be thought of as been made up of main circuit which tungsten contacts are working and the control circuit which the coil works. In the relay control circuit, it can only be controlled by tungsten contacts, in order to control its on-off, because the capacity of tungsten contacts which is used for controlling switch are smaller, therefore, the operating current is small, and it can not be used to directly control the larger load on the power consumption.

Coupled with a certain current or voltage at both ends of the coil of electromagnetic relay, magnetic flux will generate by the coil through the magnetic circuit (its compositions are the armature, yoke, core, working air gap magnetic circuit).

Under the influence of a magnetic field, armature will be attracted to the pole face of the core, thus promoting the normally open tungsten contacts are closed, and normally closed tungsten contacts open;

When the voltage or current across the coil is less than a certain value, the electromagnetic attraction is less than mechanical counterforce, the armature will return to its initial state, normally open tungsten contacts will disconnect, and normally closed tungsten contacts will connect.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Contacts in Automotive Relay

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:42

Tungsten contacts can be applied in automotive relay. Automotive relay is a relay in automotive applications, which consist of contact system, magnetic system and restoring mechanism, and tungsten contacts are used in contact systems; magnetic system is consisting of the coil, the core, the armature, etc.; restoring mechanism is composed of tension spring.

Relay is a kind of automatic control devices, when the input reaches a certain condition, so that output can change by leaps and bounds.

The environmental condition of tungsten contacts in automotive relay is harsh:

Withstanding high load power;

Standing instable voltage;

With good anti-seismic performance and its impact resistance should be better;

With corrosion resistance, tungsten contacts should be able to withstand water, salt, oil, sand, and dust, and other abuse;

Ambient temperature range requirements is : 40 ℃ ~ 125 ℃, other locations ambient temperature range is between -40 ℃and 85 ℃.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Contacts Processing Requirements

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:39

With the development of science and technology and industry, people are increasing their demand for tungsten contacts and they are stricter with tungsten contacts processing requirements, whose processing requirements of the tungsten contacts as follows:

Hardness should be higher;

Impact toughness should be better;

Rod surface should be smooth;

Thermal expansion coefficient should be smaller;

Arc-resistant performance should be better and stable;

Rod is without scratches and cracks;

Section crystal grain fibers should be short;

Section crystal grain should be uniform and fine;

Roundness, concentricity and flatness should be better;

The vapor pressure should be lower; the evaporation rate should be slower;

To meet people’s demand for tungsten contacts, the technicist of the manufacturers has done a lot of research on tungsten contacts’ physical and mechanical properties. In the production process, they comprehensively analyze the factor of tungsten contacts, such as, brittle fracture, splitting, uniform section crystal grain size, and other reasons. And they target to take a series of measures to avoid the above phenomenon.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Fluted Countersink Cutter Chatter Issue

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:34

During the machining operation, it is known that the chatter could be occurred easily even when adopting tungsten carbide countersink cutters in the cutting processes. The recommended setup in the machining is shorter and more rigid. Since the tungsten carbide fluted countersink cutters often have more than one flutes at an irregular pitching, which will reduce the smooth action of cutting edge set up. In addition the surface speed of the cutting edges, material type and the feed rate will affect the surface ripple, which is hard to remove once started.

Since if the feed rate is too small the chatter risk is likely to be increased, so the most suggested way to deal with chatter is decreasing the speed, meanwhile, increasing the feed.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

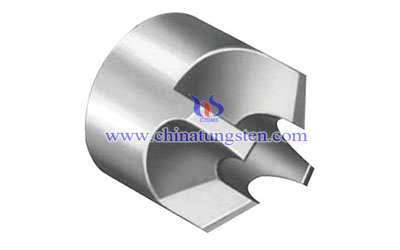

Tungsten Carbide Back Countersink Cutter

- Details

- Category: Tungsten Information

- Published on Monday, 29 June 2015 15:34

Tungsten carbide back countersink cutter is referred to a two piece countersink applied on areas that are difficult to approach. It is also known as inserted countersink cutter, since it comprises two components, a rod and cutter. The rod is inserted into the pre-drilling hole in the material while the cutter is connected to the rod, or extends out of it when it is in position.

Similar to other ‘back’ machine like back milling ,back boring, it operates on the area, which is far side of workpiece from the spindle face, without second operation set up. As it could eliminate the unnecessary repeat setting up processes, it makes effort in time saving and frustration reduction in terms of flipping over, cleaning, re-clamping , which ensures effortless high concentricity, parallelism.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com