Something about TIG from Pure Tungsten Electrode

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 18:14

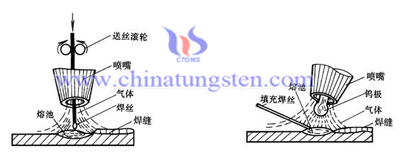

Pure tungsten electrode is the first one kind of electrode used in TIG welding technology. TIG, whose English full name is Tungsten Inert Gas, often called non-MIG welding. TIG is a kind of gas shielded welding method, in which inert gas (argon) as a protective medium, and tungsten electrode in which is only playing a conductive role without melting, there will be arcing between them when it is energized, tungsten electrode and the workpiece. During the welding process, it can be filled with wire or without wire. If you need to fill in the wire, the wire should be filled from the front of tungsten.

TIG welding can be divided into: manual welding, automatic welding, in which manual welding of pure tungsten electrode is widely used, and in the aerospace industry, it has been used on welding high-quality work.

TIG welding technology has the following advantage: good welding quality; convenient operation of the arc and the pool (due to its good visibility); without little or no slag (because it does not using flux), and you do not need to clean up slag after welding.

Pure tungsten or activated tungsten - thorium tungsten, cerium tungsten, zirconium tungsten, lanthanum tungsten, as non-consumable electrode to shield arc, and it having high quality but its welding speed is relatively slow.

Tungsten Metals Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Porous Nozzle Factors II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:39

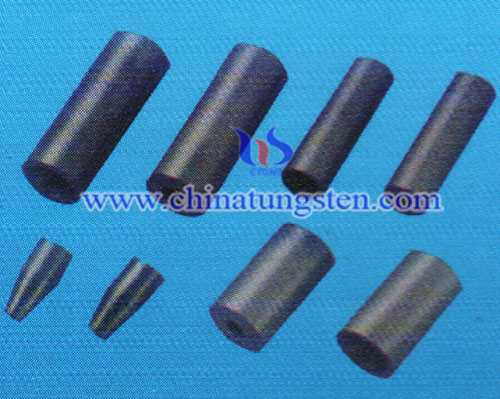

In the beginning, tungsten carbide porous nozzle uses the impact of water-flow for rock cracking. After that it depends on the returned flow for scouring the wall and associate with jet-flow pressure, which deepens the hole and increases the volume. Some related experimental statistics show that the growth of aperture will decrease with as time goes by and every type of nozzles are similar, which explains that tungsten carbide porous nozzle aperture is determined by the diameter of hole D and less influenced by quantity of holes. In addition, with the increasing numbers of spraying holes, the roundness of hole will increase. And less holes will make flow disperse and can not connect well, which make it out of round.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Porous Nozzle Factors I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:36

First of all, the time of erosion has an influence on the efficiency of tungsten carbide porous nozzle for drilling. Generally, if erosion time is longer, the aperture, hole depth and the broken volume will increase. However, the raising trends will be different due to various types of nozzles. As tungsten carbide porous nozzle, with time goes by, the hole depth and broken volume will increasing remarkably at the beginning and tend to gently. It is proves that the principle of water-flow for rock cracking is a dynamic process and has obvious periodicity.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle III

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:32

There are two common difficulties when tungsten carbide sand-blasting is working. One is the difficult suction, the other one is about abrasion. The main reason is the size of the sand entry is too small and the vacuum is not enough. While the inside blowhole do not match the straight section mixed with sand and water or the material of straight section mixed with sand and water is inappropriate so that the nozzle is badly abrasive.

Therefore, the quality of tungsten carbide sand-blasting nozzle is determined by inhaling tube diameter, the size of blowhole, the straight sections and the materials. Controlling the distance of nozzle and steel plate is the most importance to achieve the best result. In addition, adding corrosion inhibitor will prevent the metal surface from two-stage oxidation.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:30

It not only enhances the hardiness of film, but also improves mechanical and anti-fatigue performance. Regardless of inhale-type dry sand blaster, press-in dry sand blaster or fluid sand blaster, tungsten carbide nozzle is an essential part of them. The sand-blasting processing is widely used in surface derusting, which caused by electrochemical corrosion and leaves many pits on that.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Sand-blasting Nozzle I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:28

The Sand-blasting processing uses the impact energy of high-speed sand flow and compressed air to coarsening and cleaning the surface of matrix. It consists of copper mine sand, emery and quartz sand, etc. Through impacting and cutting on the surface of work pieces by grinding compound, the surface and the shape of metal work pieces will be changed for getting roughness and cleanliness.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Carbide Atomizing Nozzle Principle IV

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 17:25

According to the media, another tungsten carbide media atomizing nozzle can be specifically divided into vapor atomization, air atomization. In accordance with atomizing method can be divided into bubble atomization and pneumatic atomization. By means of fluid such as air or steam high-speed jet speed coaxial or vertical direction is atomizing liquid column or film, which also called as the two-fluid atomizing nozzle.

This kind of nozzle accelerated surrounding airflow flowing and took advantage of high-speed (normally tens of meters per second), and even ultrasonic air or steam contacted with the liquid column and film of low-speed liquid each other to vibrate, friction, finally come in to be droplets.

Tungsten Carbide Manufacturer & Supplier: Chinatungsten Online - http://www.tungsten-carbide.com.cn

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mine Enterprises in Ganzhou-II

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 16:02

The technology of producing coarse, medium, fine or superfine W/WC powder and nano size W/WC powder in Chongyi Zhangyuan, Dayu Weiliang, Ganzhou Yuan-chi etc. can catch up with the most advanced level in china. Series of products are sold to European, American and Asian markets.

1,000 tons of hard facing materials invested by Chongyi Zhangyuan and American Inframat Corporation and 1 million pieces of cemented carbide tools with its own properties invested by Chongyi Zhangyuan Tungsten Co., Ltd. are in construction. The project of 3,000 tons of cemented carbide invested by Zhongrui Company, and the project of 700 tons of tungsten rods invented by Jiangxi Yaoshen are all under construction.

Tungsten industry makes great progress in recent years. Sales value in 2006 is 11.03 billion RMB, which is 14.5 times more than that in 2000. Tax income is 1.62 billion RMB, which is 36.7 times more than that in 2000. The average growth rate of sales value is 158% and tax income 184%.

We will pay much attention to economizing resources, protecting environment and developing harmoniously. And we are taking measures in protecting environment and improving the level of utilizing resources and solving the problems due to exploring.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mine Enterprises in Ganzhou-I

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 15:58

There are 66 tungsten enterprises in Ganzhou, 19 of which are of good strength. The yearly capacity is 45,000 tons of APT, 25,000 tons of tungsten bars, 6,000 tons of W-Fe, 2 billion meters of Tungsten wire, and 3,000 tons of cemented carbide (including heavy alloy). In 2006, the shares of tungsten products in Ganzhou are Tungsten concentrate 30%, APT 65%, W-Fe 40%, W power 30%, tungsten bars 25%, tungsten wire 8% and cemented carbide 8%.

The technology of producing APT in Ganzhou is the most advanced in the world. Its technology of scheelite recovery and the mixed flotation dressing has been popularized. The technology called “Milling, ion-exchange,

continuous-crystallization” has been employed in tungsten metallurgical process in Chongyi Zhangyuan Tungsten Co. Ltd. and in APT with particle size from 1 to 50 µm and various crystal shapes could be produced. Jiangxi Tungsten Alloy Company produces W-Fe of high quality by using low-level tungsten and waste tungsten imported from abroad.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

Tungsten Mining in Ganzhou

- Details

- Category: Tungsten Information

- Published on Wednesday, 12 August 2015 15:55

Until the end of 2006, there are 53 Tungsten Mine Enterprises in Ganzhou. The yearly ore mining capacity is 6 million tons and ore processing capacity 5 million tons. Ganzhou has supplied about 1.2 million tons of tungsten concentrate since 1949, which is 49% of the total output in China. From 1980s, the recovery of tungsten mines has been improved a lot by importing new technologies. In 2006, the recovery value was about 1 billion RMB, which is 10% of the total value of Tungsten mine. Ecological environment in tungsten mines has been improved a lot by comprehensive treatment.

Ganzhou employs policies of mining tungsten strictly controlled by national mining quota. The output of tungsten concentrate has decreased 20% since 2000. Meanwhile, 2/3 of tungsten concentrate in China is processed in Ganzhou. 4,000 tons of tungsten raw material are supplied from abroad every year.

Tungsten Powder Manufacturer & Supplier: Chinatungsten Online - www.tungsten-powder.com

Tel.: 86 592 5129696; Fax: 86 592 5129797

Email: sales@chinatungsten.com

Tungsten & Molybdenum Information Bank: http://i.chinatungsten.com

Tungsten News & Tungsten Prices, 3G Version: http://3g.chinatungsten.com

Molybdenum News & Molybdenum Price: http://news.molybdenum.com.cn

sales@chinatungsten.com

sales@chinatungsten.com