Application of Tungsten Crucibles in Single Crystal Growth

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 15:07

Single crystal growth is a key process for the preparation of high-purity and structurally perfect crystals, which are widely used in semiconductors, photovoltaics, lasers and optical devices, such as the preparation of silicon single crystals, sapphire single crystals and gallium arsenide single crystals.

Application of Tungsten Crucible in High-Temperature Melting

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 15:04

High-temperature melting usually involves the preparation of metals, rare earth elements or special alloys with high melting points, and the process environment is harsh, and the requirements for container materials are extremely high. With its unique properties, tungsten crucible has become the preferred container for high-temperature smelting, and its application involving metallurgy, aerospace, rare earth smelting and other industries.

What Are the Main Applications of Tungsten Crucibles?

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 15:03

Tungsten crucibles are used in a wide range of applications due to their extremely high melting point, excellent high-temperature strength, good thermal conductivity and strong chemical inertness in vacuum or inert atmospheres.

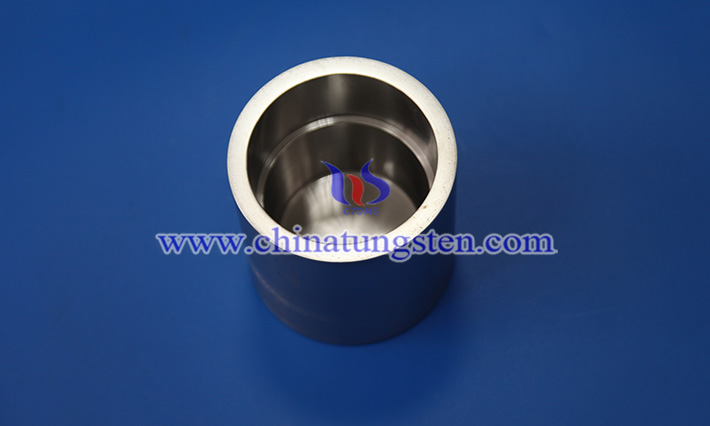

What Are the Main Properties of Tungsten Crucible?

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 15:00

The main properties of tungsten crucible include high melting point, high temperature resistance, excellent corrosion resistance, good thermal shock stability, and high strength and stability.

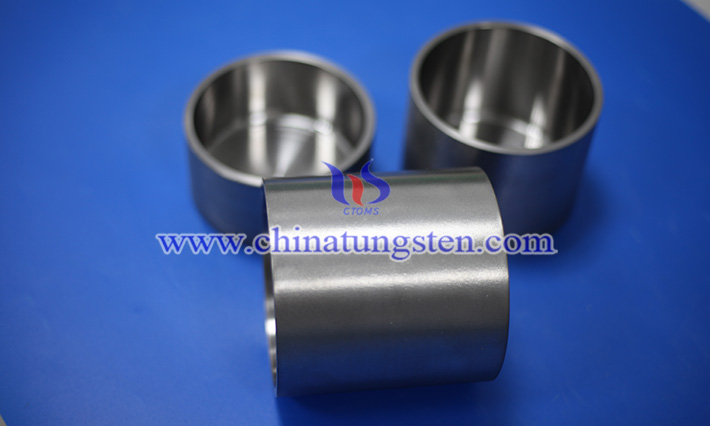

What Is Tungsten Crucible?

- Details

- Category: Tungsten Information

- Published on Tuesday, 29 April 2025 14:57

Tungsten crucible is a kind of high-temperature container made of tungsten (W) or tungsten-based alloy as the main material, which is widely used in metallurgy, materials science, semiconductor, aerospace and other fields that require ultra-high temperature treatment.

Sodium Metatungstate

- Details

- Category: Tungsten Information

- Published on Monday, 28 April 2025 19:50

Like ammonium metatungstate (AMT), sodium metatungstate is an important compound of the transition metal tungsten. It is a polymeric metatungstate formed by acidifying an isotungstate solution, exhibiting excellent physicochemical properties and widely used in density separation studies in geology, soil science, and marine biology.

Tungsten Sheet

- Details

- Category: Tungsten Information

- Published on Monday, 28 April 2025 19:47

Like tungsten bars, tungsten sheet is a typical product of the transition metal tungsten, sharing highly similar thermal, mechanical, chemical, and electrical properties, and is widely used in industries such as machinery and semiconductors.

Yellow Tungstic Acid

- Details

- Category: Tungsten Information

- Published on Monday, 28 April 2025 19:44

As a typical tungstic acid, yellow tungstic acid generally refers to a transition metal compound with a 1:1 ratio of tungsten trioxide (WO₃) to water (H₂O). It consists of one tungsten atom, two hydrogen atoms, and four oxygen atoms, forming a pale yellow crystal or powder. It is a hydrated tungsten oxide, with the English name Yellow Tungstic Acid, a molecular formula of H₂WO₄ or WO₃·H₂O, and a molecular weight of 249.86.

Tungsten Tetraboride

- Details

- Category: Tungsten Information

- Published on Monday, 28 April 2025 19:42

Like tungsten monoboride (BW), ditungsten boride (BW₂), tungsten diboride (WB₂), and ditungsten pentaboride (W₂B₅), tungsten tetraboride (WB₄) is an inorganic compound composed of the transition metal tungsten (W) and the non-metal boron (B). It exhibits excellent mechanical and electrical properties, making it valuable for applications in machining and electrode preparation under extreme conditions. Due to varying ratios of tungsten to boron atoms, different tungsten borides have distinct physicochemical properties, production methods, and applications. Below is an overview of WB₄'s basic information.

Molybdenum Acid

- Details

- Category: Tungsten Information

- Published on Monday, 28 April 2025 19:39

As an important compound of the rare metal molybdenum, molybdic acid is a colorless triclinic or yellow monoclinic solid powder formed by combining molybdenum trioxide (MoO₃) and water in a specific ratio. It is a hydrated molybdenum oxide composed of hydrogen ions (H⁺), hydroxide ions (OH⁻), and molybdate ions ((MoO₄)²⁻). Its English name is Molybdic Acid, with a molecular formula typically of MoO₃·2H₂O, a molecular weight of 179.97, and a CAS registry number of 7782-91-4.

sales@chinatungsten.com

sales@chinatungsten.com