Iron Doped Tungsten Trioxide Photocatalyst Preparation by Electrochemical Deposition

- Details

- Category: Tungsten Information

- Published on Saturday, 09 November 2019 22:47

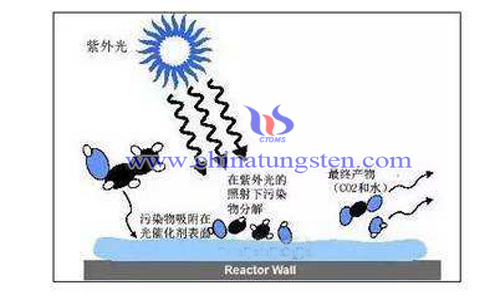

In 1972, Honda and Fujishima successfully used n-TiO2 electrode to produce hydrogen from water by photolysis of solar energy, which made people realize the application prospect of Photoelectrochemical conversion of solar energy to electric energy and chemical energy. At the same time, this technology is applied to solve the problem of dye wastewater and other industrial wastewater.

All Solid State Tungsten Oxide Electrochromic Device

- Details

- Category: Tungsten Information

- Published on Saturday, 09 November 2019 22:39

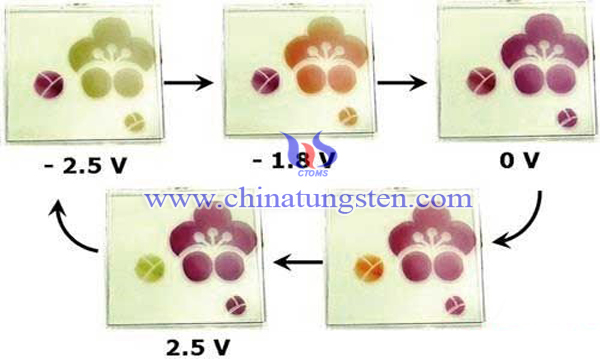

Electrochromism refers to the phenomenon that the optical properties (transmissivity, reflectance or absorptivity) of materials in the ultraviolet, visible or (and) near infrared region produce stable and reversible changes under the action of external electric field, which shows reversible changes of color and transparency in appearance.

Nickel Doped Tungsten Trioxide Catalyst

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:58

Bactericide wastewater is a typical kind of toxic and harmful industrial wastewater which is difficult to degrade, such as wastewater from pesticide industry and some chemical industry. Because of the high concentration of bactericide in wastewater, it can kill and inhibit the growth of microorganisms. On the other hand, most of the organic fungicides are polycyclic or heterocyclic organic compounds with poor biodegradability. Therefore, it is difficult to treat the bactericide wastewater directly by biotechnology.

Photocatalyst Preparation by Cerium Doped Tungsten Trioxide

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:53

Polluted wastewater and anti biotic wastewater are typical toxic and harmful industrial wastewater that are difficult to degrade, such as wastewater from pesticide industry and wastewater from some chemical industry. Because of the high concentration of fungicides in wastewater, which can kill and inhibit the growth of microorganisms, it is difficult to treat this kind of wastewater directly by biotechnology.

Hydrated Alumina Coated Tungsten Oxide Preparation by Step Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:48

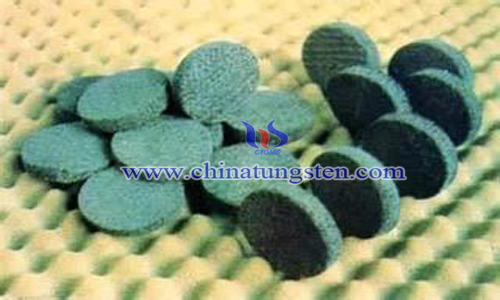

Tungsten is an irreplaceable key material in many fields due to its excellent high temperature resistance, high strength and hardness, especially in the fields of national defense industry and aerospace. Compared with the pure tungsten, the aluminum oxide coated tungsten and tungsten alloy can greatly increase the strength of tungsten, refine the grains, reduce the particle size, increase the toughness and tensile strength of the material.

A Simple Gas Sensing Material of Tungsten Oxide Nanowire by Hydrothermal Method

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:40

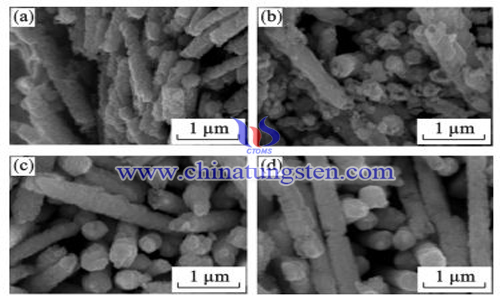

Through a simple hydrothermal method, the researchers prepared a wide range of tungsten oxide nanowire gas sensing materials on a large scale, and then provided a tungsten oxide nanowire sensor with high sensitivity, good repeatability and high stability for H2, CO and NH3. The operation process is as follows:

Residual Alkali Recovery from Tungsten Smelting

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:31

Scheelite is a troublesome raw material in tungsten smelting. After the popularization of alkaline pressure leaching technology in the last century, the smelting capacity and scale of scheelite have been greatly improved, and the technology and process have been further mature. Due to the use of excessive alkali process, although a large part of alkali is consumed in the leaching process, the amount of residual alkali in the crude sodium tungstate solution is still very high after the reaction.

Hydrothermal Synthesis of Tungsten Oxide Nanowires

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 23:09

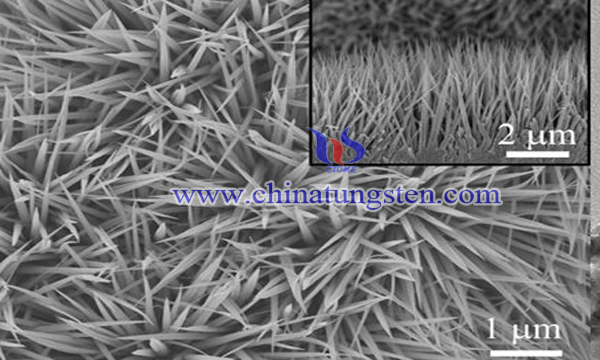

Tungsten oxide is a kind of transition metal oxide, which belongs to n-type semiconductor. At present, a large number of researches have found that w-based oxides not only act as catalytic, electrochromic, solar energy absorbing and invisible materials, but also have the characteristics of semiconductor functional materials such as heat sensitive, pressure-sensitive and gas sensitive.

High Performance Tungsten Oxide Preparation by Photocatalyst

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 22:59

In recent years, with the development of industrialization and the rapid improvement of people's living standards, environmental pollution has become the main problem facing human beings, especially water pollution, which has attracted more and more attention. Industrial waste water accounts for a large part of the water pollution sources. Because of its dark color and strong toxicity, it is difficult to treat.

One Step Reduction of Tungsten Powder

- Details

- Category: Tungsten Information

- Published on Friday, 08 November 2019 22:54

To produce tungsten powder from ammonium paratungstate, it is usually necessary to first burn tungsten oxide in a weak reducing atmosphere, and then carry out hydrogen reduction to produce tungsten powder. Most of the tungsten powders prepared by this process are very regular polycrystalline, which are the main raw materials for the preparation of tungsten alloy and tungsten carbide.

sales@chinatungsten.com

sales@chinatungsten.com