Tungsten Vanadium Copper Composite Materials by Ball Milling

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:57

Among the many vanadium oxides, vanadium dioxide is different because of its rapid and sudden phase transition. Its phase transition temperature is 68 ℃, which can change reversibly from low temperature monoclinic system to high temperature tetragonal system, making its physical properties such as resistivity, optical transmittance and magnetic conductivity change greatly. This characteristic makes it have a great prospect in intelligent switch, electronic device and photoelectric equipment. The results show that tungsten can effectively reduce the phase transition temperature of vanadium dioxide, and copper can improve the conductivity of vanadium dioxide.

Silica Bismuth - Tungstate Composite Photocatalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:50

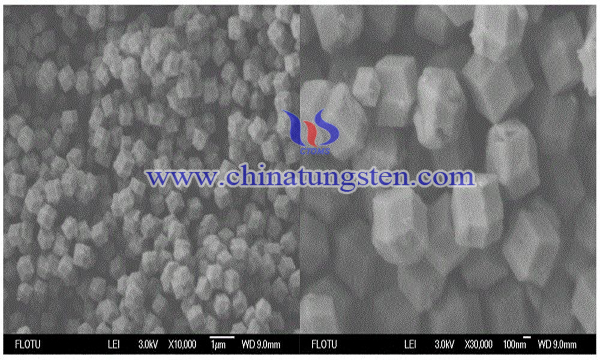

Silica bismuth is a typical semiconductor material. Through the action of light, electrons are excited by light to transition and leave corresponding holes, forming electron hole pairs. These photo generated electron hole pairs have strong redox ability and are easy to react with organics and polymers. Due to the narrow band gap, they respond well to visible light;

Manganese Tungstate Composite Manganese Dioxide Catalyst

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:46

With the development of science and technology, toxic organic pollutants from industrial and agricultural production seriously threaten the environment and human health. It is of great significance to seek a new and efficient environmental treatment technology. Photocatalytic technology has become a new environmental treatment technology with important application prospect because of its advantages of energy saving, high efficiency, complete pollutant degradation and no secondary pollution.

Epoxy Catalyzed by Phosphomolybdophosphate Tungstophosphoric Acid

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:42

Heteropolyacids have been developed for more than 100 years, and the research contents have been gradually extended to material chemistry, electrochemistry, catalytic chemistry, photochemistry, surface science, medicine and other fields. Therefore, heteropolyacids show high catalytic activity and selectivity for various organic reactions.

Indium Ferrocyanide Tungsten Trioxide Film

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:33

In architecture, through glass doors and windows is the main source of energy loss. In China, the energy loss through glass doors and windows can be as high as 40% - 50% of the total building energy consumption. At the same time, especially in today's society, the large-scale use of glass wall aggravates the loss of building energy consumption.

Sheet Silver Nickel Tungsten Electrical Contact

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 11:16

Silver nickel electrical contact has been widely used in various low-voltage electrical appliances because of its good thermal conductivity, low and stable contact resistance, excellent processing performance and other advantages. However, due to its poor anti fusion welding performance, the application range of silver nickel electrical contact is affected.

Tungsten Carbide Shell Coated Lithium Iron Phosphate Cathode Material

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 10:00

Cathode materials have been the bottleneck to improve the performance and reduce the cost of lithium-ion batteries. Lithium iron phosphate is the first choice of cathode materials for modern commercial lithium-ion batteries because of its low price, high energy density, long life and good safety. However, the low electronic conductivity of lithium iron phosphate seriously hinders its application in the field of power and energy storage batteries.

Heat Resistant Water-based Nano Tungsten Disulfide Isothermal Forging Lubricant

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 09:42

Tungsten disulfide (WS2) is a kind of layered solid lubricant with structure similar to graphite. It has excellent high temperature resistance, extreme pressure resistance, good adsorption capacity on metal surface and low thermal conductivity. WS2 was first applied to the lubrication of the key parts of the American mariner spacecraft, and it was used to prepare high temperature extreme pressure grease and energy-saving engine lubricating oil, with good application results.

Nano Tungsten Carbide Powder for Shield Cutting Tools

- Details

- Category: Tungsten Information

- Published on Tuesday, 12 November 2019 09:35

At present, China's major cities are booming in the construction of rail transit projects. Because of its unparalleled advantages, shield method has been widely used in the construction of rail transit tunnels.

Rare Earth Doped Tungsten Oxide Nanostructured Films

- Details

- Category: Tungsten Information

- Published on Monday, 11 November 2019 10:30

Rare earth trivalent ions have rich 4f energy level configuration, and their fluorescence characteristics are greatly affected by the crystal field environment and the symmetry of the lattice. At present, many scholars use the small size effect of semiconductor nano materials (ZnO, TiO2) and lattice sensitization to improve the optical properties of rare earth trivalent ions, which are widely used in biological fluorescent probes, optical devices and new luminescent materials.

sales@chinatungsten.com

sales@chinatungsten.com